Energy

Tesla’s Origin Story in One Giant Infographic

Priced at $17 per share just seven years ago, the Tesla IPO ended up being a total bargain for anyone lucky enough to get in.

However, this view comes with the benefit of plenty of hindsight – and even Elon Musk would tell you that it wasn’t always obvious that the company would be around in 2017. There were periods of time when layoffs were rampant, the company’s payroll was covered by credit cards, and Tesla was on the brink of bankruptcy.

Rise of Tesla: The History (Part 1 of 3)

Today’s massive infographic comes to us from Global Energy Metals, and it is the first part of our three-part Rise of Tesla Series, which will soon be a definitive source for everything you ever wanted to know about the company.

Part 1 deals with the origin story of the company, challenges faced by the first EVs, the company’s strategy and initial execution, and the Tesla Roadster’s development.

Tesla was initially conceived in 2003 out of the vision of two Silicon Valley engineers, Martin Eberhard and Marc Tarpenning. The partners had just sold their eReader company for $187 million, and were looking for their next big idea.

The infamous “death” of GM’s EV1 electric car that year ended up being a source of inspiration, and the two engineers started looking into ways to reduce the world’s reliance on Middle Eastern oil and to combat climate change.

The electric car pathway was not just better than the other choices that were out there – it was dramatically better.

– Martin Eberhard, Tesla co-founder

The company was bootstrapped until Elon Musk led the $7.5 million Series A round in February 2004 and became the controlling investor. He joined the board of directors as its chairman, and took on operational roles as well.

At this time, JB Straubel – who famously rebuilt an electric golf cart when he was only 14 years old – also joined the company as CTO.

Initial Strategy

Tesla’s initial strategy was to build a high performance sports car first, for a few reasons:

- It would shed the existing stigma around EVs

- Sports cars have higher margins

- Fewer cars would need to be produced

- High-end buyers are less price-sensitive

Instead of building the Tesla Roadster from scratch, the company aimed to combine an existing chassis with an AC induction motor and battery. And so, the company signed a contract with British sports car maker Lotus to use its Elise chassis as a base.

Roadster Debut

The Roadster made its debut at a star-studded launch party in Santa Monica. The 350-strong guestlist of Hollywood celebrities and the press were wowed by the 2-seater sports car with a $100,000 price tag.

This is not your father’s electric car.

– The Washington Post

What the audience didn’t notice?

The Roadsters had many issues that needed to be fixed – these and others would delay Tesla well beyond the planned Summer 2007 delivery date.

The Dark Years

Tesla’s original business plan was built on the idea that the auto industry had changed drastically.

Automakers now focused on core competencies like financing, engine design, sales and marketing, and final assembly – getting the hundreds of individual car parts, like windshield wiper blades or door handles, was actually outsourced.

This was supposed to make it easy for Tesla to get its foot in the door – to focus on the EV aspect and let Lotus do the rest. Instead, the company experienced an “elegance creep” phenomenon. They were able to keep making the car nicer, but it meant customizing individual parts.

Costs spiraled out of control, things got delayed, and the car began to take a very different shape than the Elise. By the time it was said and done, the Tesla Roadster was nothing like its Lotus cousin, sharing only 7% parts by count.

The Revolving Door

During this process, there was a revolving door of CEOs.

2007: Eberhart was forced to resign as CEO in August

2007: Early Tesla investor Michael Marks took the reins temporarily

2007: In November, Ze’ev Drori took over as CEO and President

2008: After less than a year of Drori’s run, Musk stepped in to take over the role in October

At this point, Musk had already invested $55 million in the company, and it was teetering towards bankruptcy.

I’ve got so many chips on the table with Tesla. It just made sense for me to have both hands on the wheel.

– Elon Musk

Some of Musk’s first moves:

- He ended up cutting 25% of the workforce

- He leaned on friends to help cover payroll, week-to-week

- He raised a $40 debt financing round to escape bankruptcy

- He formed a strategic partnership with Daimler AG, which acquired a 10% stake of Tesla for $50 million

- He took a $465 million loan from the U.S. Dept. of Energy (He repaid it back ahead of the deadline)

- He recalled 75% of the Roadsters produced between March 2008 and April 2009

Despite revamping the entire production process – and the company itself – Tesla made it through its most trying time.

The Roadster’s Run

The Roadster wasn’t perfect, but it helped Tesla learn what it meant to be a car company.

It is not just a car, but one of the strongest automotive statements on the road.

– Car and Driver

A total of 2,450 units were produced, and the specs were impressive for an EV. With a top speed of 125 mph and a 0-60 mph time of 3.7 seconds, the Roadster helped dispel many of the myths surrounding electric cars.

Meanwhile, the Roadster’s lithium-ion battery also was the first step forward in an entire battery revolution. The 992 lb (450 kg) battery for the Roadster contained 6,831 lithium ion cells arranged into 11 “sheets” connected in series, and gave the car a range of 244 miles.

With the Roadster, Tesla would not only set itself up for future success, but also the transformation of an entire industry.

This was Part 1 of the Tesla Series. Parts 2 and 3, on Tesla as well as the future vision, will be released in the near future!

Energy

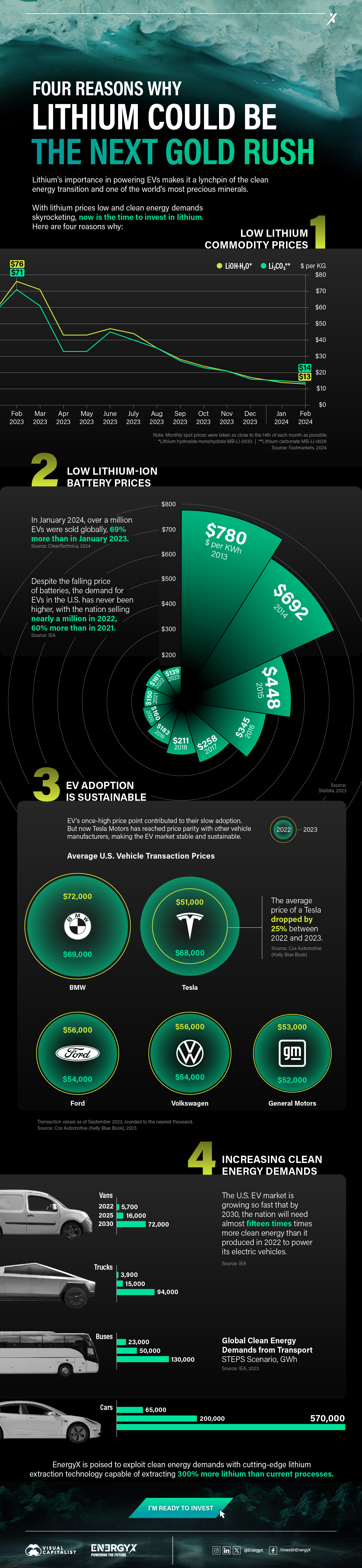

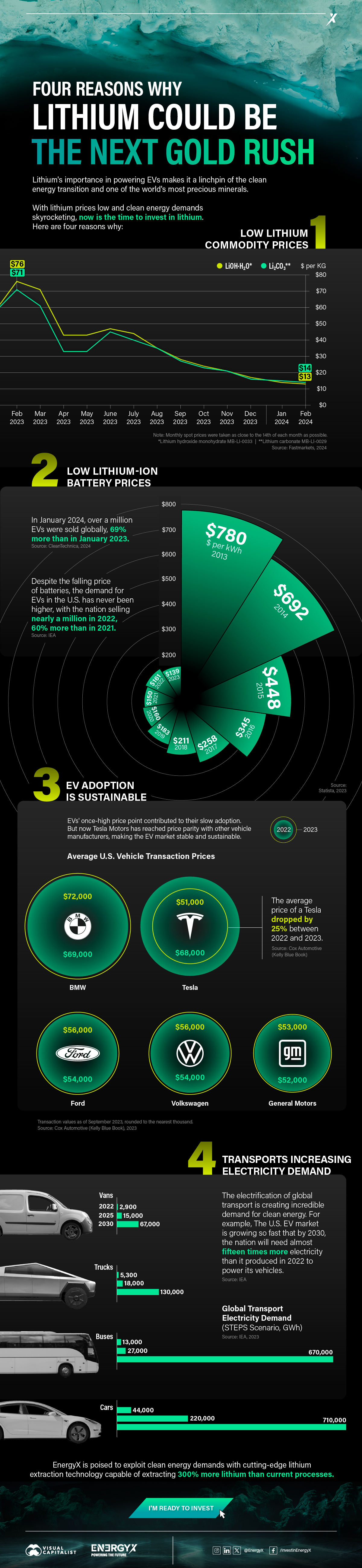

Charted: 4 Reasons Why Lithium Could Be the Next Gold Rush

Visual Capitalist has partnered with EnergyX to show why drops in prices and growing demand may make now the right time to invest in lithium.

4 Reasons Why You Should Invest in Lithium

Lithium’s importance in powering EVs makes it a linchpin of the clean energy transition and one of the world’s most precious minerals.

In this graphic, Visual Capitalist partnered with EnergyX to explore why now may be the time to invest in lithium.

1. Lithium Prices Have Dropped

One of the most critical aspects of evaluating an investment is ensuring that the asset’s value is higher than its price would indicate. Lithium is integral to powering EVs, and, prices have fallen fast over the last year:

| Date | LiOH·H₂O* | Li₂CO₃** |

|---|---|---|

| Feb 2023 | $76 | $71 |

| March 2023 | $71 | $61 |

| Apr 2023 | $43 | $33 |

| May 2023 | $43 | $33 |

| June 2023 | $47 | $45 |

| July 2023 | $44 | $40 |

| Aug 2023 | $35 | $35 |

| Sept 2023 | $28 | $27 |

| Oct 2023 | $24 | $23 |

| Nov 2023 | $21 | $21 |

| Dec 2023 | $17 | $16 |

| Jan 2024 | $14 | $15 |

| Feb 2024 | $13 | $14 |

Note: Monthly spot prices were taken as close to the 14th of each month as possible.

*Lithium hydroxide monohydrate MB-LI-0033

**Lithium carbonate MB-LI-0029

2. Lithium-Ion Battery Prices Are Also Falling

The drop in lithium prices is just one reason to invest in the metal. Increasing economies of scale, coupled with low commodity prices, have caused the cost of lithium-ion batteries to drop significantly as well.

In fact, BNEF reports that between 2013 and 2023, the price of a Li-ion battery dropped by 82%.

| Year | Price per KWh |

|---|---|

| 2023 | $139 |

| 2022 | $161 |

| 2021 | $150 |

| 2020 | $160 |

| 2019 | $183 |

| 2018 | $211 |

| 2017 | $258 |

| 2016 | $345 |

| 2015 | $448 |

| 2014 | $692 |

| 2013 | $780 |

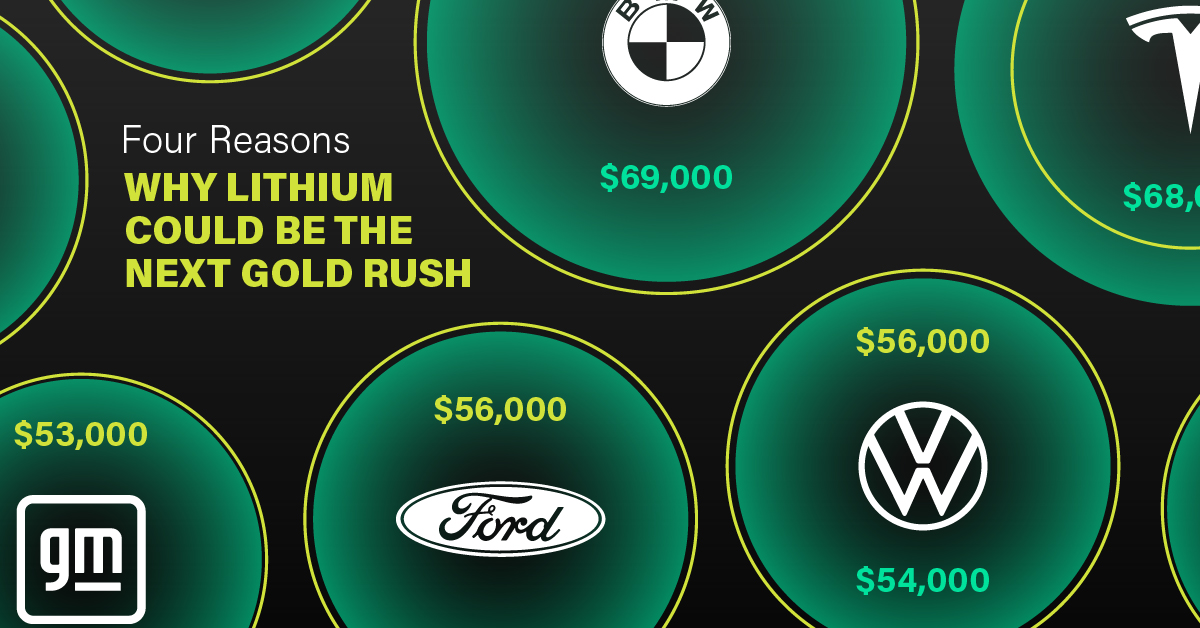

3. EV Adoption is Sustainable

One of the best reasons to invest in lithium is that EVs, one of the main drivers behind the demand for lithium, have reached a price point similar to that of traditional vehicle.

According to the Kelly Blue Book, Tesla’s average transaction price dropped by 25% between 2022 and 2023, bringing it in line with many other major manufacturers and showing that EVs are a realistic transport option from a consumer price perspective.

| Manufacturer | September 2022 | September 2023 |

|---|---|---|

| BMW | $69,000 | $72,000 |

| Ford | $54,000 | $56,000 |

| Volkswagon | $54,000 | $56,000 |

| General Motors | $52,000 | $53,000 |

| Tesla | $68,000 | $51,000 |

4. Electricity Demand in Transport is Growing

As EVs become an accessible transport option, there’s an investment opportunity in lithium. But possibly the best reason to invest in lithium is that the IEA reports global demand for the electricity in transport could grow dramatically by 2030:

| Transport Type | 2022 | 2025 | 2030 |

|---|---|---|---|

| Buses 🚌 | 23,000 GWh | 50,000 GWh | 130,000 GWh |

| Cars 🚙 | 65,000 GWh | 200,000 GWh | 570,000 GWh |

| Trucks 🛻 | 4,000 GWh | 15,000 GWh | 94,000 GWh |

| Vans 🚐 | 6,000 GWh | 16,000 GWh | 72,000 GWh |

The Lithium Investment Opportunity

Lithium presents a potentially classic investment opportunity. Lithium and battery prices have dropped significantly, and recently, EVs have reached a price point similar to other vehicles. By 2030, the demand for clean energy, especially in transport, will grow dramatically.

With prices dropping and demand skyrocketing, now is the time to invest in lithium.

EnergyX is poised to exploit lithium demand with cutting-edge lithium extraction technology capable of extracting 300% more lithium than current processes.

-

Lithium4 days ago

Lithium4 days agoRanked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

-

Energy1 week ago

Energy1 week agoThe World’s Biggest Nuclear Energy Producers

China has grown its nuclear capacity over the last decade, now ranking second on the list of top nuclear energy producers.

-

Energy1 month ago

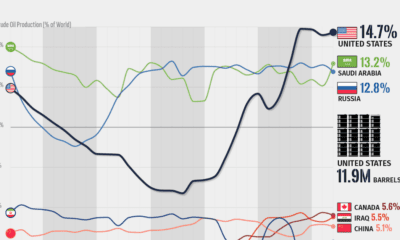

Energy1 month agoThe World’s Biggest Oil Producers in 2023

Just three countries accounted for 40% of global oil production last year.

-

Energy1 month ago

Energy1 month agoHow Much Does the U.S. Depend on Russian Uranium?

Currently, Russia is the largest foreign supplier of nuclear power fuel to the U.S.

-

Uranium2 months ago

Uranium2 months agoCharted: Global Uranium Reserves, by Country

We visualize the distribution of the world’s uranium reserves by country, with 3 countries accounting for more than half of total reserves.

-

Energy3 months ago

Energy3 months agoVisualizing the Rise of the U.S. as Top Crude Oil Producer

Over the last decade, the United States has established itself as the world’s top producer of crude oil, surpassing Saudi Arabia and Russia.

-

Education1 week ago

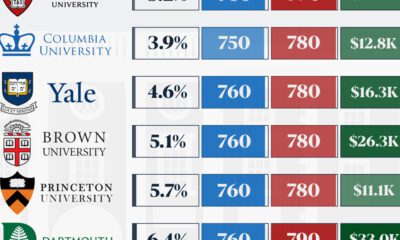

Education1 week agoHow Hard Is It to Get Into an Ivy League School?

-

Technology2 weeks ago

Technology2 weeks agoRanked: Semiconductor Companies by Industry Revenue Share

-

Markets2 weeks ago

Markets2 weeks agoRanked: The World’s Top Flight Routes, by Revenue

-

Demographics2 weeks ago

Demographics2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries

-

Economy2 weeks ago

Economy2 weeks agoWhere U.S. Inflation Hit the Hardest in March 2024

-

Green2 weeks ago

Green2 weeks agoTop Countries By Forest Growth Since 2001