Energy

Tesla’s Journey: From IPO to Passing Ford in Value, in Just 7 Years

In Tesla’s final years as a private company, things got pretty hectic.

As we showed in Part 1: Tesla’s Origin Story, the launch of the Roadster was a public relations success, but it created all kinds of problems internally. There were massive cost overruns, a revolving door of CEOs, layoffs, and even a narrow escape from bankruptcy.

Fortunately, by 2010 the company was able to forget these troubles after a successful IPO. The company secured $226 million in capital, and hitting the public markets started a roller coaster ride of growth.

Rise of Tesla: The Company (Part 2 of 3)

Today’s giant infographic comes to us from Global Energy Metals, and it is the second part of our three-part Rise of Tesla Series, which is a definitive source for everything you ever wanted to know about the company.

Part 2 shows major events from 2010 until today, and it tracks the company’s rapid growth along the way.

Tesla was the first American car company to IPO since The Ford Motor Company went public in 1956.

Interestingly, it only took seven years for Tesla to match Ford’s value – here are the major events during this stretch of time that made this incredible feat possible.

2010

After securing funding from the public markets, Tesla was positioned for its next big leap:

- The company had just narrowly escaped bankruptcy

- The Tesla Roadster helped to dispel the stigma around EVs, but it was unclear if it could be parlayed into mainstream success

- The company was free from its feud and lawsuit with co-founder Martin Eberhard

- Tesla had just taken over its now famous factory in Fremont, CA

It was time to focus on the next phase of Tesla’s strategy: to build the company’s first real car from scratch – and to help the company achieve the economies of scale, impact, and reputation it desired.

2011

In 2011, Tesla announces that the Roadster will be officially discontinued.

Instead, the company starts focusing all efforts on two new EVs: the Model S (A full-size luxury car) and the Model X (A full-size luxury crossover SUV).

2012

The Model S was Tesla’s chance to build a car around the electric powertrain, rather than the other way around.

When we started Model S, it was a clean sheet of paper.

– Franz Von Holzhausen, Chief Car Designer

In June 2012, the first Model S hits the road – and the rest is history. The model won multiple awards, including being recognized as the “safest car ever tested” by the NHTSA and the “Best car ever tested” by Consumer Reports. Over 200,000 cars were eventually sold.

But despite the success of the new model, Tesla still faced a giant problem. Lithium-ion batteries were still too expensive for a mass market car to be feasible, and the company needed to “bet the farm” on an idea to bring EVs to the mainstream.

2013

Tesla reveals initial plans for its Gigafactory concept, an ambitious attempt to bring economies of scale to the battery industry.

In time, the details of those plans solidified:

- Cost: $5 billion

- Partner: Panasonic

- Objective: To reduce the cost of lithium-ion battery packs by 30%

- Location: Sparks, Nevada

- Size: Up to 5.8 million sq. ft (100 football fields)

The company believed that through economies of scale, reduction of waste, a closer supply chain, vertical integration, and process optimization, that the cost of batteries could be sufficiently reduced to make a mass market EV possible.

Under Tesla’s first plan, the Gigafactory would be ramped up to produce batteries for 500,000 EVs per year by 2020. Later on, the company eventually moved that target forward by two years.

2014

Tesla makes significant advances in software, hardware, and its mission.

- Autopilot is released for the first time, which gives the Model S semi-autonomous driving and parking capabilities

- By this time, Tesla’s Supercharger network is up to 221 stations around the world

- Tesla goes open source, releasing all of the company’s patents for anyone to use

2015

After massive and repeated delays because of issues with the “falcon wing” doors, the Model X finally is released.

In the same year, the Tesla Powerwall is also announced. Using a high-capacity lithium-ion battery and proprietary technology – the Powerwall is a major step towards Tesla achieving its major end goal of integrating energy generation and storage in the home.

2016

Tesla unveils its Model 3 – the car for the masses that is supposed to change it all.

Here are the specs for the most basic model, which is available at $35,000:

- Price: $35,000

- Torque: 415 lb-ft

- Power: 235 hp (Motor Trend’s est.)

- 0-60 mph: 5.6 seconds

- Top speed: 130 mph

- Range: 220 miles

After being announced, the Model 3 quickly garnered 500,000 pre-orders. To put the magnitude of this number in perspective – in six years of production of the Model S, the company has only delivered about 200,000 cars in total so far.

In 2016, Tesla also announces that it is taking over of Elon Musk’s other companies, SolarCity, for $2.6 billion of stock. Elon Musk owns 22% of SolarCity shares at the time of the takeover.

The goal: to build a seamlessly integrated battery and solar product that looks beautiful.

2017

2017 was a whirlwind year for Tesla:

- Consumer Reports names Tesla the top American car brand in 2017

- The Tesla Gigafactory I begins battery cell production

- Tesla wins bids to provide grid-scale battery power in South Australia and Puerto Rico

- Tesla starts accepting orders for its new solar roof product

- The Tesla Semi is unveiled – a semi-truck that can go 0-60 mph in just 5 seconds, which is 3x faster than a diesel truck

- Model 3 deliveries begin, though production issues keep them from ramping at the speed anticipated

Tesla also unveils the new Roadster – the second-gen version of the car that started it all.

This time, it has unbelievable specs:

- 0-60 mph: 1.9 seconds

- 200 kWh battery pack

- Top speed: above 250 mph

- 620 mile range (It could drive from San Francisco to LA and back, without needing a recharge)

The point of doing this is to give a hardcore smackdown to gasoline cars

– Elon Musk, Tesla Co-Founder and CEO

The new Roadster will go into production in 2020.

A Look to the Future

In 1956, the IPO of the Ford Motor Company was the single largest IPO in Wall Street’s history.

Tesla IPO’d a whopping 54 years later, and the company has already passed Ford in value:

Ford: $49.9B

Tesla: $52.3B

(numbers from Dec 31, 2017)

An incredible feat, it took only seven years for Tesla to pass Ford in value on the public markets. However, this is still the beginning of Tesla’s story.

See Musk’s vision for the future in Part 3 of this series.

Energy

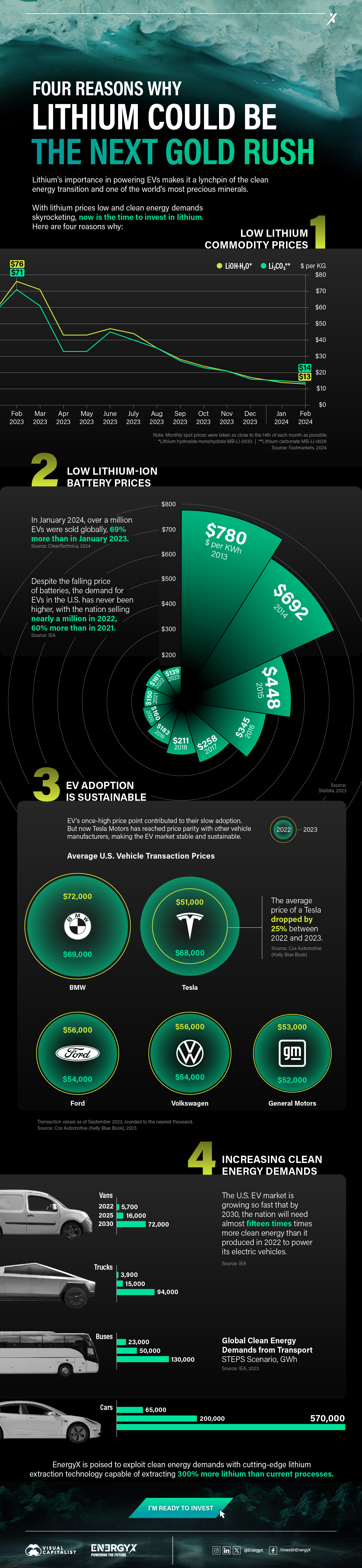

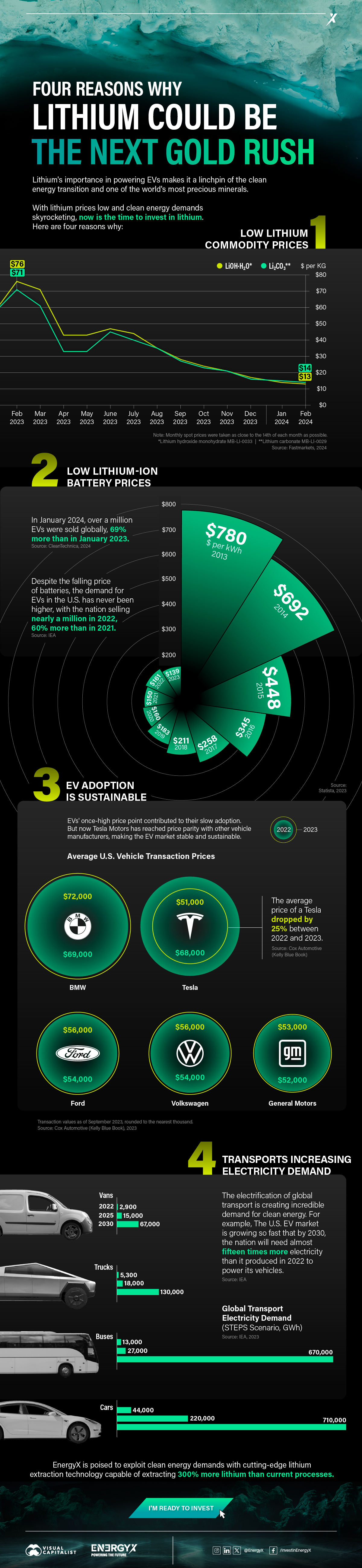

Charted: 4 Reasons Why Lithium Could Be the Next Gold Rush

Visual Capitalist has partnered with EnergyX to show why drops in prices and growing demand may make now the right time to invest in lithium.

4 Reasons Why You Should Invest in Lithium

Lithium’s importance in powering EVs makes it a linchpin of the clean energy transition and one of the world’s most precious minerals.

In this graphic, Visual Capitalist partnered with EnergyX to explore why now may be the time to invest in lithium.

1. Lithium Prices Have Dropped

One of the most critical aspects of evaluating an investment is ensuring that the asset’s value is higher than its price would indicate. Lithium is integral to powering EVs, and, prices have fallen fast over the last year:

| Date | LiOH·H₂O* | Li₂CO₃** |

|---|---|---|

| Feb 2023 | $76 | $71 |

| March 2023 | $71 | $61 |

| Apr 2023 | $43 | $33 |

| May 2023 | $43 | $33 |

| June 2023 | $47 | $45 |

| July 2023 | $44 | $40 |

| Aug 2023 | $35 | $35 |

| Sept 2023 | $28 | $27 |

| Oct 2023 | $24 | $23 |

| Nov 2023 | $21 | $21 |

| Dec 2023 | $17 | $16 |

| Jan 2024 | $14 | $15 |

| Feb 2024 | $13 | $14 |

Note: Monthly spot prices were taken as close to the 14th of each month as possible.

*Lithium hydroxide monohydrate MB-LI-0033

**Lithium carbonate MB-LI-0029

2. Lithium-Ion Battery Prices Are Also Falling

The drop in lithium prices is just one reason to invest in the metal. Increasing economies of scale, coupled with low commodity prices, have caused the cost of lithium-ion batteries to drop significantly as well.

In fact, BNEF reports that between 2013 and 2023, the price of a Li-ion battery dropped by 82%.

| Year | Price per KWh |

|---|---|

| 2023 | $139 |

| 2022 | $161 |

| 2021 | $150 |

| 2020 | $160 |

| 2019 | $183 |

| 2018 | $211 |

| 2017 | $258 |

| 2016 | $345 |

| 2015 | $448 |

| 2014 | $692 |

| 2013 | $780 |

3. EV Adoption is Sustainable

One of the best reasons to invest in lithium is that EVs, one of the main drivers behind the demand for lithium, have reached a price point similar to that of traditional vehicle.

According to the Kelly Blue Book, Tesla’s average transaction price dropped by 25% between 2022 and 2023, bringing it in line with many other major manufacturers and showing that EVs are a realistic transport option from a consumer price perspective.

| Manufacturer | September 2022 | September 2023 |

|---|---|---|

| BMW | $69,000 | $72,000 |

| Ford | $54,000 | $56,000 |

| Volkswagon | $54,000 | $56,000 |

| General Motors | $52,000 | $53,000 |

| Tesla | $68,000 | $51,000 |

4. Electricity Demand in Transport is Growing

As EVs become an accessible transport option, there’s an investment opportunity in lithium. But possibly the best reason to invest in lithium is that the IEA reports global demand for the electricity in transport could grow dramatically by 2030:

| Transport Type | 2022 | 2025 | 2030 |

|---|---|---|---|

| Buses 🚌 | 23,000 GWh | 50,000 GWh | 130,000 GWh |

| Cars 🚙 | 65,000 GWh | 200,000 GWh | 570,000 GWh |

| Trucks 🛻 | 4,000 GWh | 15,000 GWh | 94,000 GWh |

| Vans 🚐 | 6,000 GWh | 16,000 GWh | 72,000 GWh |

The Lithium Investment Opportunity

Lithium presents a potentially classic investment opportunity. Lithium and battery prices have dropped significantly, and recently, EVs have reached a price point similar to other vehicles. By 2030, the demand for clean energy, especially in transport, will grow dramatically.

With prices dropping and demand skyrocketing, now is the time to invest in lithium.

EnergyX is poised to exploit lithium demand with cutting-edge lithium extraction technology capable of extracting 300% more lithium than current processes.

-

Lithium4 days ago

Lithium4 days agoRanked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

-

Energy1 week ago

Energy1 week agoThe World’s Biggest Nuclear Energy Producers

China has grown its nuclear capacity over the last decade, now ranking second on the list of top nuclear energy producers.

-

Energy1 month ago

Energy1 month agoThe World’s Biggest Oil Producers in 2023

Just three countries accounted for 40% of global oil production last year.

-

Energy1 month ago

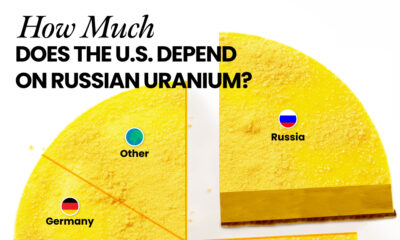

Energy1 month agoHow Much Does the U.S. Depend on Russian Uranium?

Currently, Russia is the largest foreign supplier of nuclear power fuel to the U.S.

-

Uranium2 months ago

Uranium2 months agoCharted: Global Uranium Reserves, by Country

We visualize the distribution of the world’s uranium reserves by country, with 3 countries accounting for more than half of total reserves.

-

Energy3 months ago

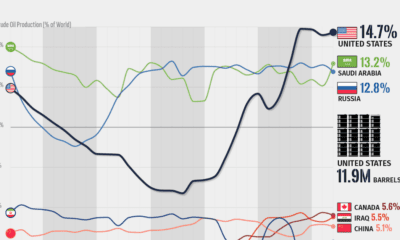

Energy3 months agoVisualizing the Rise of the U.S. as Top Crude Oil Producer

Over the last decade, the United States has established itself as the world’s top producer of crude oil, surpassing Saudi Arabia and Russia.

-

Debt1 week ago

Debt1 week agoHow Debt-to-GDP Ratios Have Changed Since 2000

-

Markets2 weeks ago

Markets2 weeks agoRanked: The World’s Top Flight Routes, by Revenue

-

Countries2 weeks ago

Countries2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries

-

United States2 weeks ago

United States2 weeks agoWhere U.S. Inflation Hit the Hardest in March 2024

-

Green2 weeks ago

Green2 weeks agoTop Countries By Forest Growth Since 2001

-

United States2 weeks ago

United States2 weeks agoRanked: The Largest U.S. Corporations by Number of Employees