Energy

The Future of Battery Technology

The Battery Series

Part 5: The Future of Battery Technology

The Battery Series is a five-part infographic series that explores what investors need to know about modern battery technology, including raw material supply, demand, and future applications.

Presented by: Nevada Energy Metals, eCobalt Solutions Inc., and Great Lakes Graphite

The Future of Battery Technology

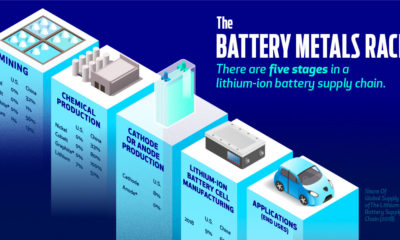

This is the last installment of the Battery Series. For a recap of what has been covered so far, see the evolution of battery technology, the energy problem in context, the reasons behind the surge in lithium-ion demand, and the critical materials needed to make lithium-ion batteries.

There’s no doubt that the lithium-ion battery has been an important catalyst for the green revolution, but there is still much work to be done for a full switch to renewable energy.

The battery technology of the future could:

- Make electric cars a no-brainer choice for any driver.

- Make grid-scale energy storage solutions cheap and efficient.

- Make a full switch to renewable energy more feasible.

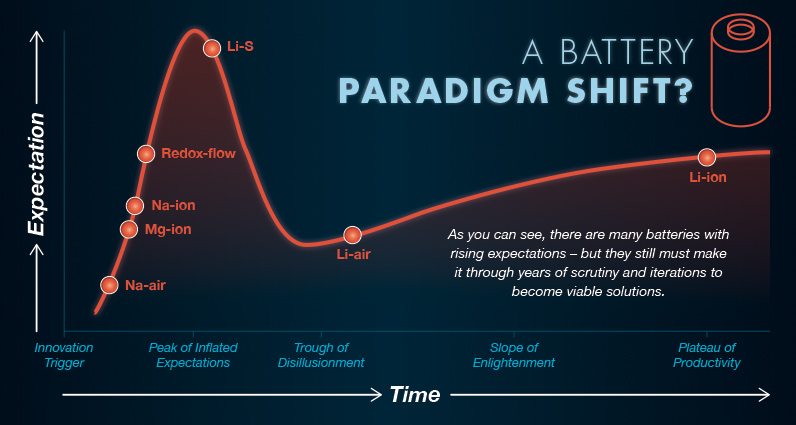

Right now, scientists see many upcoming battery innovations that have the promise to do this. However, the road to commercialization is long, arduous, and filled with many unexpected obstacles.

The Near-Term: Improving the Li-Ion

For the foreseeable future, the improvement of battery technology relies on modifications being made to already-existing lithium-ion technology. In fact, experts estimate that lithium-ions will continue to increase capacity by 6-7% annually for a number of years.

Here’s what’s driving those advances:

Efficient Manufacturing

Tesla has already made significant advances in battery design and production through its Gigafactory:

- Better engineering and manufacturing processes.

- Wider and longer cell design allows more materials packaged into each cell.

- New battery cooling system allows to fit more cells into battery pack.

Better Cathodes

Most of the recent advances in lithium-ion energy density have come from manipulating the relative quantities of cobalt, aluminum, manganese, and nickel in the cathodes. By 2020, 75% of batteries are expected to contain cobalt in some capacity.

For scientists, its about finding the materials and crystal structures that can store the maximum amount of ions. The next generation of cathodes may be born from lithium-rich layered oxide materials (LLOs) or similar approaches, such as the nickel-rich variety.

Better Anodes

While most lithium-ion progress to date has come from cathode tinkering, the biggest advances might happen in the anode.

Current graphite anodes can only store one lithium atom for every six carbon atoms – but silicon anodes could store 4.4 lithium atoms for every one silicon atom. That’s a theoretical 10x increase in capacity!

However, the problem with this is well-documented. When silicon houses these lithium ions, it ends up bloating in size up to 400%. This volume change can cause irreversible damage to the anode, making the battery unusable.

To get around this, scientists are looking at a few different solutions.

1. Encasing silicon in a graphene “cage” to prevent cracking after expansion.

2. Using silicon nanowires, which can better handle the volume change.

3. Adding silicon in tiny amounts using existing manufacturing processes – Tesla is rumored to already be doing this.

Solid-State Lithium-Ion

Lastly, a final improvement that is being worked on for the lithium-ion battery is to use a solid-state setup, rather than having liquid electrolytes enabling the ion transfer. This design could increase energy density in the future, but it still has some problems to resolve first, such as ions moving too slowing through the solid electrolyte.

The Long-Term: Beyond the Lithium-ion

Here are some new innovations in the pipeline that could help enable the future of battery technology:

Lithium-Air

Anode: Lithium

Cathode: Porous carbon (Oxygen)

Promise: 10x greater energy density than Li-ion

Problems: Air is not pure enough and would need to be filtered. Lithium and oxygen form peroxide films that produce a barrier, ultimately killing storage capacity. Cycle life is only 50 cycles in lab tests.

Variations: Scientists also trying aluminum-air and sodium-air batteries as well.

Lithium-Sulphur

Anode: Lithium

Cathode: Sulphur, Carbon

Promise: Lighter, cheaper, and more powerful than li-ion

Problems: Volume expansion of up to 80%, causing mechanical stress. Unwanted reactions with electrolytes. Poor conductivity and poor stability at higher temperatures.

Variations: Many different variations exist, including using graphite/graphene, and silicon in the chemistry.

Vanadium Flow Batteries

Catholyte: Vanadium

Anolyte: Vanadium

Promise: Using vanadium ions in different oxidation states to store chemical potential energy at scale. Can be expanded simply by using larger electrolyte tanks.

Problems: Poor energy-to-volume ratio. Very heavy; must be used in stationary applications.

Variations: Scientists are experimenting with other flow battery chemistries as well, such as zinc-bromine.

Battery Series: Conclusion

While the future of battery technology is very exciting, for the near and medium terms, scientists are mainly focused on improving the already-commercialized lithium-ion.

What does the battery market look like 15 to 20 years from now? It’s ultimately hard to say. However, it’s likely that some of these new technologies above will help in leading the charge to a 100% renewable future.

Thanks for taking a look at The Battery Series.

Energy

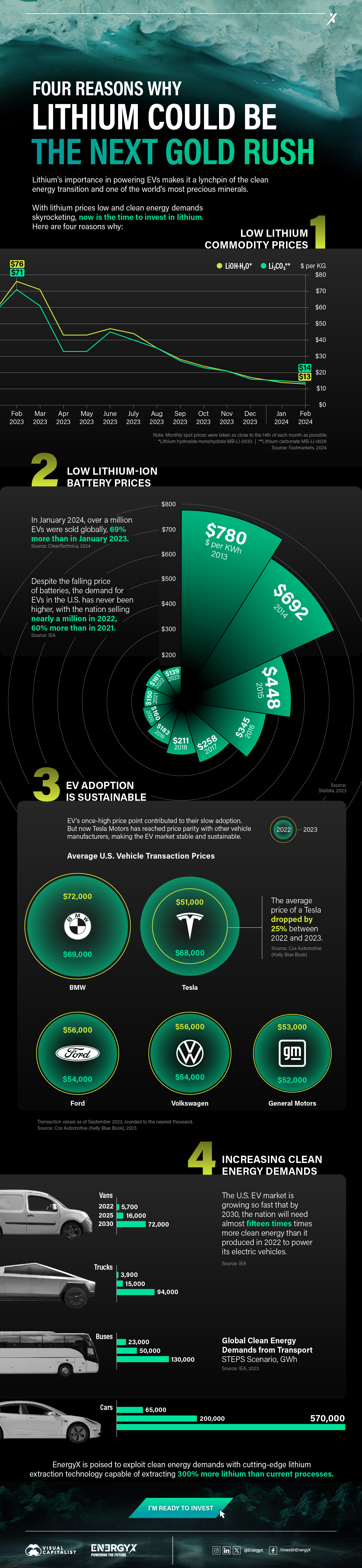

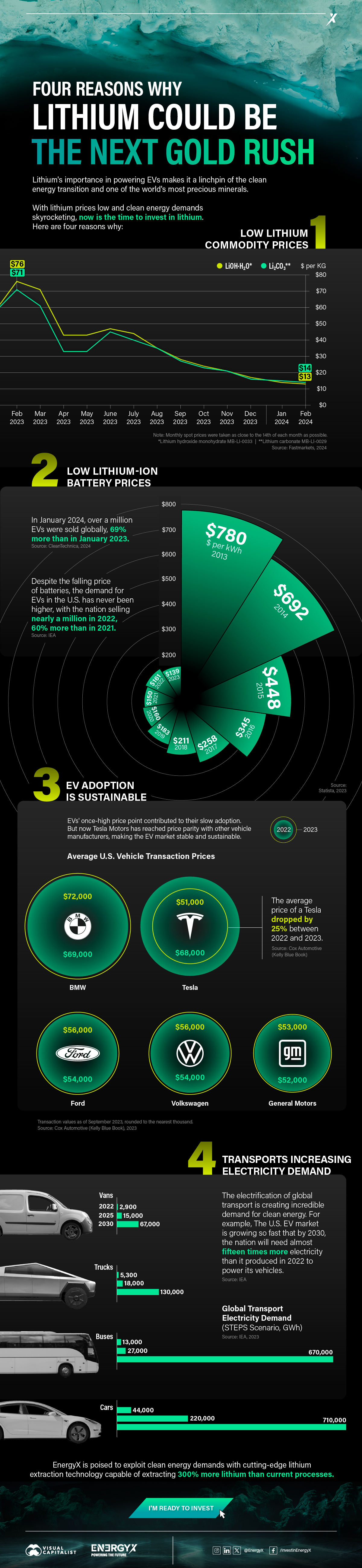

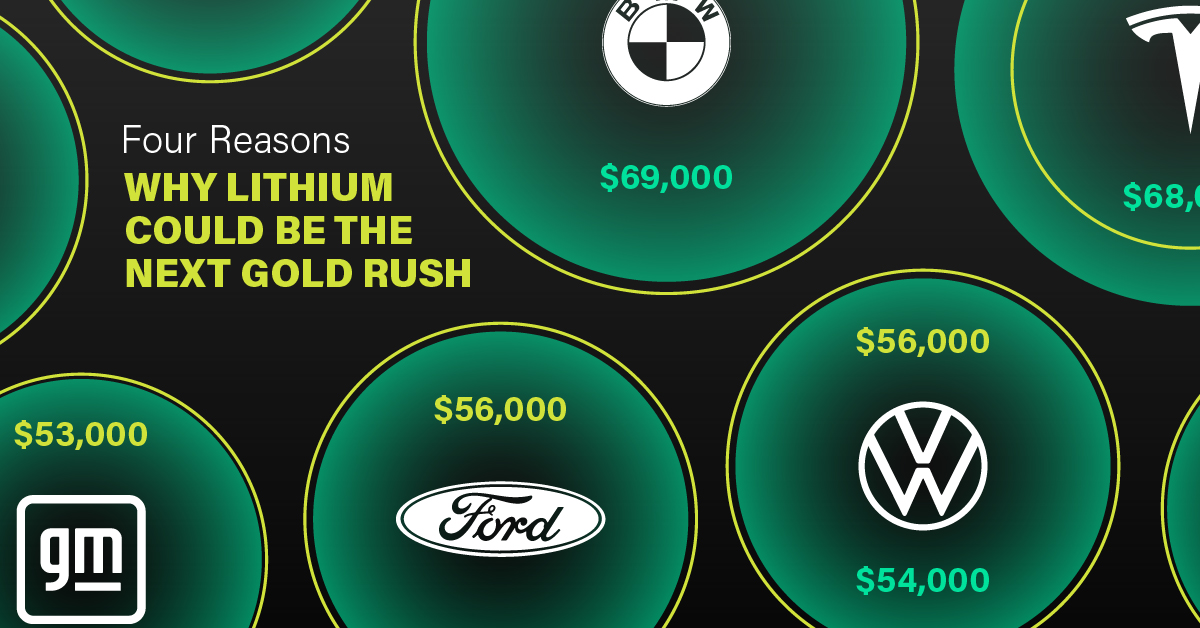

Charted: 4 Reasons Why Lithium Could Be the Next Gold Rush

Visual Capitalist has partnered with EnergyX to show why drops in prices and growing demand may make now the right time to invest in lithium.

4 Reasons Why You Should Invest in Lithium

Lithium’s importance in powering EVs makes it a linchpin of the clean energy transition and one of the world’s most precious minerals.

In this graphic, Visual Capitalist partnered with EnergyX to explore why now may be the time to invest in lithium.

1. Lithium Prices Have Dropped

One of the most critical aspects of evaluating an investment is ensuring that the asset’s value is higher than its price would indicate. Lithium is integral to powering EVs, and, prices have fallen fast over the last year:

| Date | LiOH·H₂O* | Li₂CO₃** |

|---|---|---|

| Feb 2023 | $76 | $71 |

| March 2023 | $71 | $61 |

| Apr 2023 | $43 | $33 |

| May 2023 | $43 | $33 |

| June 2023 | $47 | $45 |

| July 2023 | $44 | $40 |

| Aug 2023 | $35 | $35 |

| Sept 2023 | $28 | $27 |

| Oct 2023 | $24 | $23 |

| Nov 2023 | $21 | $21 |

| Dec 2023 | $17 | $16 |

| Jan 2024 | $14 | $15 |

| Feb 2024 | $13 | $14 |

Note: Monthly spot prices were taken as close to the 14th of each month as possible.

*Lithium hydroxide monohydrate MB-LI-0033

**Lithium carbonate MB-LI-0029

2. Lithium-Ion Battery Prices Are Also Falling

The drop in lithium prices is just one reason to invest in the metal. Increasing economies of scale, coupled with low commodity prices, have caused the cost of lithium-ion batteries to drop significantly as well.

In fact, BNEF reports that between 2013 and 2023, the price of a Li-ion battery dropped by 82%.

| Year | Price per KWh |

|---|---|

| 2023 | $139 |

| 2022 | $161 |

| 2021 | $150 |

| 2020 | $160 |

| 2019 | $183 |

| 2018 | $211 |

| 2017 | $258 |

| 2016 | $345 |

| 2015 | $448 |

| 2014 | $692 |

| 2013 | $780 |

3. EV Adoption is Sustainable

One of the best reasons to invest in lithium is that EVs, one of the main drivers behind the demand for lithium, have reached a price point similar to that of traditional vehicle.

According to the Kelly Blue Book, Tesla’s average transaction price dropped by 25% between 2022 and 2023, bringing it in line with many other major manufacturers and showing that EVs are a realistic transport option from a consumer price perspective.

| Manufacturer | September 2022 | September 2023 |

|---|---|---|

| BMW | $69,000 | $72,000 |

| Ford | $54,000 | $56,000 |

| Volkswagon | $54,000 | $56,000 |

| General Motors | $52,000 | $53,000 |

| Tesla | $68,000 | $51,000 |

4. Electricity Demand in Transport is Growing

As EVs become an accessible transport option, there’s an investment opportunity in lithium. But possibly the best reason to invest in lithium is that the IEA reports global demand for the electricity in transport could grow dramatically by 2030:

| Transport Type | 2022 | 2025 | 2030 |

|---|---|---|---|

| Buses 🚌 | 23,000 GWh | 50,000 GWh | 130,000 GWh |

| Cars 🚙 | 65,000 GWh | 200,000 GWh | 570,000 GWh |

| Trucks 🛻 | 4,000 GWh | 15,000 GWh | 94,000 GWh |

| Vans 🚐 | 6,000 GWh | 16,000 GWh | 72,000 GWh |

The Lithium Investment Opportunity

Lithium presents a potentially classic investment opportunity. Lithium and battery prices have dropped significantly, and recently, EVs have reached a price point similar to other vehicles. By 2030, the demand for clean energy, especially in transport, will grow dramatically.

With prices dropping and demand skyrocketing, now is the time to invest in lithium.

EnergyX is poised to exploit lithium demand with cutting-edge lithium extraction technology capable of extracting 300% more lithium than current processes.

-

Lithium5 days ago

Lithium5 days agoRanked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

-

Energy1 week ago

Energy1 week agoThe World’s Biggest Nuclear Energy Producers

China has grown its nuclear capacity over the last decade, now ranking second on the list of top nuclear energy producers.

-

Energy1 month ago

Energy1 month agoThe World’s Biggest Oil Producers in 2023

Just three countries accounted for 40% of global oil production last year.

-

Energy1 month ago

Energy1 month agoHow Much Does the U.S. Depend on Russian Uranium?

Currently, Russia is the largest foreign supplier of nuclear power fuel to the U.S.

-

Uranium2 months ago

Uranium2 months agoCharted: Global Uranium Reserves, by Country

We visualize the distribution of the world’s uranium reserves by country, with 3 countries accounting for more than half of total reserves.

-

Energy3 months ago

Energy3 months agoVisualizing the Rise of the U.S. as Top Crude Oil Producer

Over the last decade, the United States has established itself as the world’s top producer of crude oil, surpassing Saudi Arabia and Russia.

-

Sports1 week ago

Sports1 week agoThe Highest Earning Athletes in Seven Professional Sports

-

Countries2 weeks ago

Countries2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries

-

United States2 weeks ago

United States2 weeks agoWhere U.S. Inflation Hit the Hardest in March 2024

-

Green2 weeks ago

Green2 weeks agoTop Countries By Forest Growth Since 2001

-

United States2 weeks ago

United States2 weeks agoRanked: The Largest U.S. Corporations by Number of Employees

-

Maps2 weeks ago

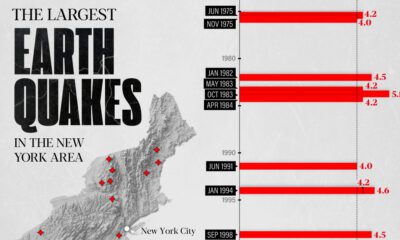

Maps2 weeks agoThe Largest Earthquakes in the New York Area (1970-2024)