Visualizing The Global Semiconductor Supply Chain

The following content is sponsored by ASE Global

![]()

Visualizing The Global Semiconductor Supply Chain

Our digitally-driven society is powered by an extremely robust semiconductor supply chain, and until the COVID-19 pandemic, not many people thought about it.

But a sudden surge in demand for digital goods, improved technologies, and recovering economies put the strain and spotlight directly on semiconductors.

The millions of digital devices we use, from smartphones to electric cars, computers, robotics, and the businesses they enable, only function thanks to the intricate chips built on semiconductors. By some estimates, up to 22.5% of global GDP is made up by the global digital economy.

This graphic from ASE Global highlights the complex and global semiconductor supply chain that powers our modern world.

How Important are Semiconductors and Chips?

Fully understanding the importance of semiconductors to the modern world is sometimes tricky, especially when the devices themselves are so small.

But a semiconductor device—also known as an integrated circuit (IC) or chip—actually contains many smaller circuits comprised of millions of transistors, all packed onto a few millimeters of silicon (the semiconductor).

These semiconductor devices allow electronics to make computations, and in essence, function and operate. That makes them vital for modern electronics, with semiconductors being the fourth-most traded product in the world behind crude oil, motor vehicle parts, and refined oil.

Here’s a breakdown of different applications of semiconductor devices by market sizes in 2019:

| Semiconductor Applications by Market (2019) | Market Size |

|---|---|

| Smartphone | 25.3% |

| Personal Computing | 20.5% |

| Servers, Data Centers, Storage | 14.6% |

| Industrial Electronics | 11.7% |

| Consumer Electronics | 10.0% |

| Automotive | 9.8% |

| Wired/wireless Infrastructure | 8.1% |

Modern smartphones, for example, utilize semiconductor devices with many different smaller integrated circuits for different functions. For example, these modern chips can include the phone’s CPU, GPU, neural processing, and image processing cores.

And as the recent strain on automotive manufacturing demonstrated, semiconductors are even vital for vehicles. Cars are packed with up to 1,400 semiconductor devices controlling everything from airbags to the engine, and electric vehicles utilize even more.

What the Semiconductor Supply Chain Looks Like

So how do these complex devices make their way from concept to your devices?

An integrated semiconductor supply chain that involves thousands of companies, millions of people, and billions of dollars. The chain can be broken up into stages which happen across the globe, better known as the foundry model:

- Design: Semiconductor chip designs are created for specific or general device usage.

- Manufacturing (Front End): Silicon wafers are processed through an extensive series of manufacturing steps then diced into multiple chips (also called dies or devices).

- Manufacturing (Back End): Chips are layered and assembled into packages that can be mounted onto circuit boards. Packaged chips are then tested under different electrical and temperature conditions.

- End Product Integration: Chips are integrated by electronics and equipment manufacturers to create end products for consumers.

- Consumption: End products are shipped to companies, retailer, and consumers worldwide.

The entire process, from starting design and production to end product integration, takes months. But in the end, those manufactured chips end up in smartphones, computers, cars, servers, smart homes, and other technology all around the globe.

Different Types of Companies in Semiconductor Manufacturing

In 2020, despite an economic slowdown from the pandemic, an estimated 1.4 trillion semiconductor chip units were shipped around the globe.

Those chips were manufactured by many types of companies that occupy different parts of the supply chain. Some are household names in electronics, while others are lesser-known manufacturing stage companies responsible for most of the world’s chip consumption.

These companies operate under the foundry model, which is also known as fabless design. The model outsources different stages of production to specialized companies:

- Fabless semiconductor companies and electronics manufacturers (and independent design companies) create the design and specifications required for their chips.

- Foundries are contracted to manufacture the designed chips.

- OSAT (outsourced semiconductor assembly & test) companies assemble, package, and test the chips for consumption. ASE Global is the market leader in assembly and testing services, capturing 30% of the global OSAT market in 2021.

- OEM (original equipment manufacturers) and contracted EMS (electronics manufacturing service) companies integrate the packaged chip into devices. ASE Global is also a leading EMS provider, and over the course of the company’s history, has helped manufacture more than three trillion chips.

- Devices are then sold by the fabless companies and electronics manufacturers at the start of the chain.

At the same time, there are also IDMs (integrated device manufacturers) that design, manufacture and sell their own chips. This was the traditional model of chip development and IDMS generally weren’t considered a part of the foundry model, but many IDMs now outsource part of their production cycles as well.

Unlocking the Potential of the Digital Economy

The companies that make up the semiconductor supply chain are spread all over the globe, from the U.S. to China, South Korea, Taiwan, and Germany. A finished chip can contain components that have traveled more than 25,000 miles by the time of final product integration.

It’s a complicated but necessary supply chain that empowers the technology of the present and the future. From advances in 5G and AI to smart factories and advances in automotive and quantum computing, the companies in the semiconductor supply chain make it all possible.

-

Sponsored3 years ago

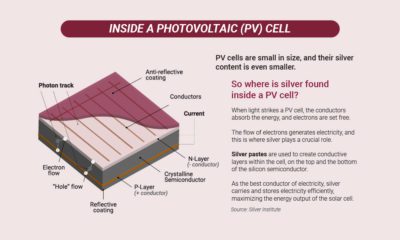

Sponsored3 years agoMore Than Precious: Silver’s Role in the New Energy Era (Part 3 of 3)

Long known as a precious metal, silver in solar and EV technologies will redefine its role and importance to a greener economy.

-

Sponsored7 years ago

Sponsored7 years agoThe History and Evolution of the Video Games Market

Everything from Pong to the rise of mobile gaming and AR/VR. Learn about the $100 billion video games market in this giant infographic.

-

Sponsored8 years ago

Sponsored8 years agoThe Extraordinary Raw Materials in an iPhone 6s

Over 700 million iPhones have now been sold, but the iPhone would not exist if it were not for the raw materials that make the technology...

-

Sponsored8 years ago

Sponsored8 years agoThe Industrial Internet, and How It’s Revolutionizing Mining

The convergence of the global industrial sector with big data and the internet of things, or the Industrial Internet, will revolutionize how mining works.