Energy

Lithium: The Fuel of the Green Revolution

Lithium: The Fuel of the Green Revolution

The world is shifting greener.

And while people have always wanted electric cars and inexpensive solar power, the reality is that until recently, battery technology just wasn’t good enough to store energy on an economical or practical basis.

Things have changed, and the green revolution has been kickstarted by battery power. The commercialization of the lithium-ion battery has solved a crucial green energy problem for two major reasons that can be related back to the properties of lithium:

1) Lithium has extremely high electrochemical potential, and so do lithium-ion cells:

| Battery cell | Typical Voltage |

|---|---|

| Lithium-ion (Cobalt) | 3.6V |

| Lead Acid | 2.0V |

| NiMH | 1.2V |

| NiCd | 1.2V |

This means one lithium-ion cell can do more – making it much more efficient to use in everything from electronics to energy storage.

2) Lithium is also the lightest metal on the periodic table. Batteries need to be as light as possible, especially in electric cars.

How Lithium Gets Used

2001

Many years ago, lithium was used chiefly for a variety of industrial purposes. Major sources of lithium demand included ceramics, glass, aluminum production, lubricants, and as a catalyst for rubber production.

2015

In modern times, with the commercialization of the lithium-ion, batteries are now the major source of demand for lithium at 39%.

2025

According to a report by Deutsche Bank, in 2025 the battery market for lithium alone will be more than 2x bigger than the total lithium market today.

About 70% of all lithium will go to electric vehicles, e-bikes, traditional batteries, and energy storage, making it the uncontested fuel of the green revolution.

Major Lithium Drivers

Lithium-ion battery demand is primarily driven by rapid growth in the electric vehicle market, which is expected to make up 35% of all vehicle demand by 2040.

But renewable energy storage also plays a role in driving lithium demand. With solar and wind energy being installed at a rapid pace, that means more batteries must be procured to store this energy. This can be done for a home system with a product like Tesla’s Powerwall 2.0, and it is being done on a utility scale as well.

Two Types of Lithium

Prices for lithium have skyrocketed in the last two years – and it is worth knowing the two different types of lithium used by the market.

Lithium carbonate:

This is the first chemical in the production chain, and as a result, sells for less than lithium hydroxide. It can be used as cathode material in some batteries, such as the Nissan Leaf, where it is used in a LMO with NMC formulation (Lithium manganese oxide / nickel manganese cobalt oxide chemistries)

Lithium hydroxide:

This is a by-product of lithium carbonate, created by a metathesis reaction with calcium hydroxide. It can be used to produce cathode material more efficiently and is actually necessary for some types of cathodes. It’s used in the Tesla Powerwall and Model S, for example.

Lithium Mining

There are two basic ways to extract lithium: from brine or from hard rock. The latter mainly consists of spodumene production.

Brine deposits represent about 66% of global lithium resources, and are found mainly in the salt flats of Chile, Argentina, Bolivia, China, and Tibet.

The most famous area for lithium is known as the Lithium Triangle, located on the border between Chile, Argentina, and Bolivia. Salar de Atacama, the world’s third largest salt flat, resides on the Chilean side, and contains about 50% of global reserves.

The largest lithium producers in 2015 were Chile (37%) and Australia (33%). Argentina is the only other double-digit producer at 11%.

Lithium is Fueling the Green Revolution

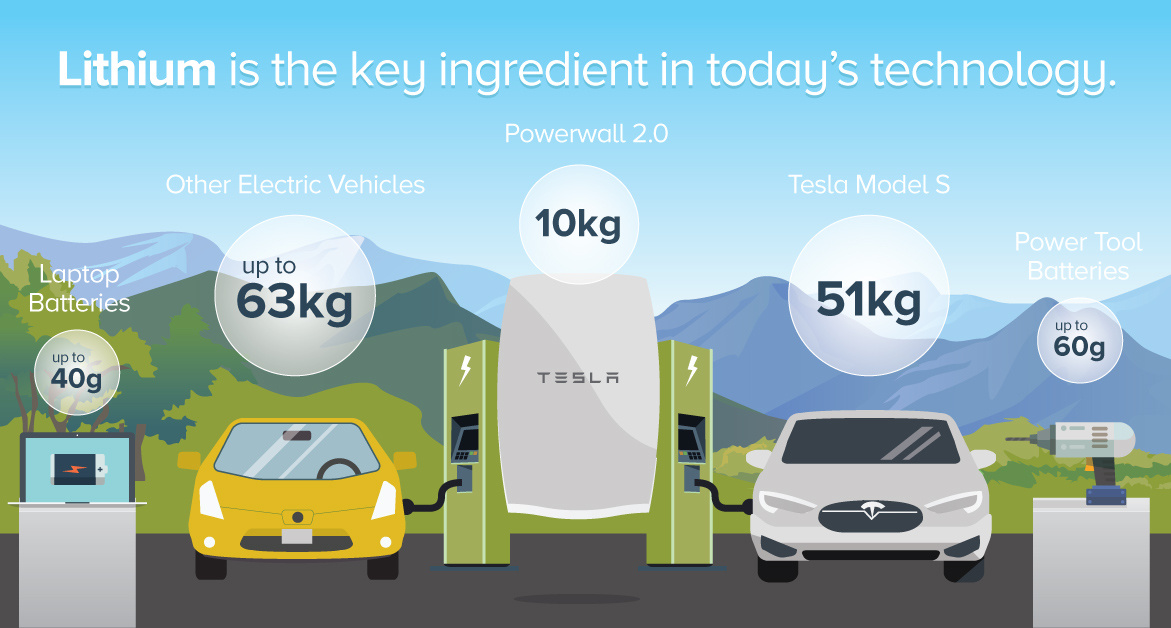

Here’s the estimated amount of lithium that can be found in everyday items using lithium-ion batteries:

Tesla Model S: 51kg

Electric Vehicles: 10-63kg

Tesla Powerwall 2.0: 10kg

Hybrids: 0.8kg to 2.0kg

Power tool batteries: 40-60g

Laptops: 30-40g

Tablets: 20-30g

Mobile phones: 2-3g

Energy

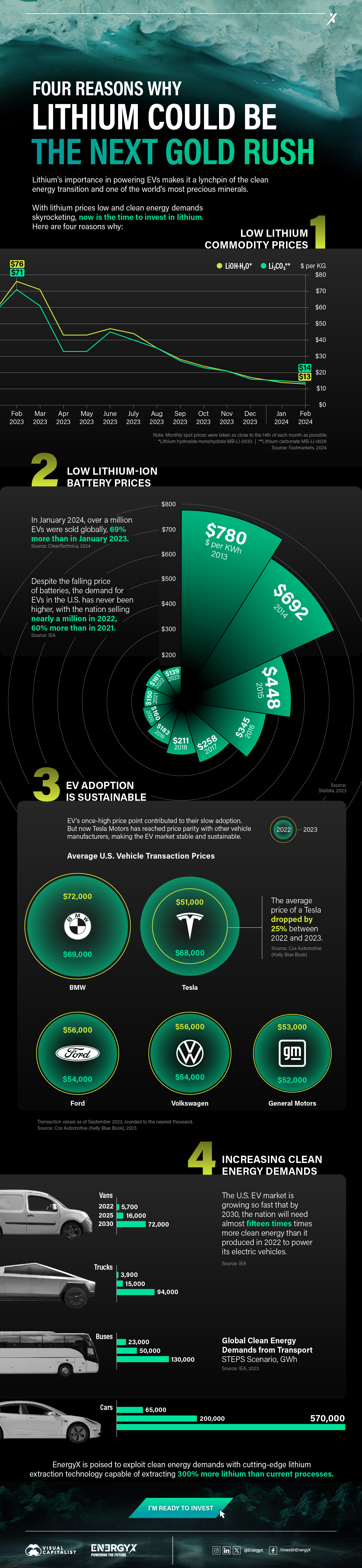

Charted: 4 Reasons Why Lithium Could Be the Next Gold Rush

Visual Capitalist has partnered with EnergyX to show why drops in prices and growing demand may make now the right time to invest in lithium.

4 Reasons Why You Should Invest in Lithium

Lithium’s importance in powering EVs makes it a linchpin of the clean energy transition and one of the world’s most precious minerals.

In this graphic, Visual Capitalist partnered with EnergyX to explore why now may be the time to invest in lithium.

1. Lithium Prices Have Dropped

One of the most critical aspects of evaluating an investment is ensuring that the asset’s value is higher than its price would indicate. Lithium is integral to powering EVs, and, prices have fallen fast over the last year:

| Date | LiOH·H₂O* | Li₂CO₃** |

|---|---|---|

| Feb 2023 | $76 | $71 |

| March 2023 | $71 | $61 |

| Apr 2023 | $43 | $33 |

| May 2023 | $43 | $33 |

| June 2023 | $47 | $45 |

| July 2023 | $44 | $40 |

| Aug 2023 | $35 | $35 |

| Sept 2023 | $28 | $27 |

| Oct 2023 | $24 | $23 |

| Nov 2023 | $21 | $21 |

| Dec 2023 | $17 | $16 |

| Jan 2024 | $14 | $15 |

| Feb 2024 | $13 | $14 |

Note: Monthly spot prices were taken as close to the 14th of each month as possible.

*Lithium hydroxide monohydrate MB-LI-0033

**Lithium carbonate MB-LI-0029

2. Lithium-Ion Battery Prices Are Also Falling

The drop in lithium prices is just one reason to invest in the metal. Increasing economies of scale, coupled with low commodity prices, have caused the cost of lithium-ion batteries to drop significantly as well.

In fact, BNEF reports that between 2013 and 2023, the price of a Li-ion battery dropped by 82%.

| Year | Price per KWh |

|---|---|

| 2023 | $139 |

| 2022 | $161 |

| 2021 | $150 |

| 2020 | $160 |

| 2019 | $183 |

| 2018 | $211 |

| 2017 | $258 |

| 2016 | $345 |

| 2015 | $448 |

| 2014 | $692 |

| 2013 | $780 |

3. EV Adoption is Sustainable

One of the best reasons to invest in lithium is that EVs, one of the main drivers behind the demand for lithium, have reached a price point similar to that of traditional vehicle.

According to the Kelly Blue Book, Tesla’s average transaction price dropped by 25% between 2022 and 2023, bringing it in line with many other major manufacturers and showing that EVs are a realistic transport option from a consumer price perspective.

| Manufacturer | September 2022 | September 2023 |

|---|---|---|

| BMW | $69,000 | $72,000 |

| Ford | $54,000 | $56,000 |

| Volkswagon | $54,000 | $56,000 |

| General Motors | $52,000 | $53,000 |

| Tesla | $68,000 | $51,000 |

4. Electricity Demand in Transport is Growing

As EVs become an accessible transport option, there’s an investment opportunity in lithium. But possibly the best reason to invest in lithium is that the IEA reports global demand for the electricity in transport could grow dramatically by 2030:

| Transport Type | 2022 | 2025 | 2030 |

|---|---|---|---|

| Buses 🚌 | 23,000 GWh | 50,000 GWh | 130,000 GWh |

| Cars 🚙 | 65,000 GWh | 200,000 GWh | 570,000 GWh |

| Trucks 🛻 | 4,000 GWh | 15,000 GWh | 94,000 GWh |

| Vans 🚐 | 6,000 GWh | 16,000 GWh | 72,000 GWh |

The Lithium Investment Opportunity

Lithium presents a potentially classic investment opportunity. Lithium and battery prices have dropped significantly, and recently, EVs have reached a price point similar to other vehicles. By 2030, the demand for clean energy, especially in transport, will grow dramatically.

With prices dropping and demand skyrocketing, now is the time to invest in lithium.

EnergyX is poised to exploit lithium demand with cutting-edge lithium extraction technology capable of extracting 300% more lithium than current processes.

-

Lithium5 days ago

Lithium5 days agoRanked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

-

Energy1 week ago

Energy1 week agoThe World’s Biggest Nuclear Energy Producers

China has grown its nuclear capacity over the last decade, now ranking second on the list of top nuclear energy producers.

-

Energy1 month ago

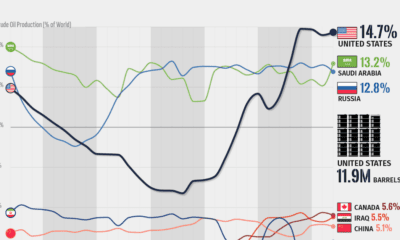

Energy1 month agoThe World’s Biggest Oil Producers in 2023

Just three countries accounted for 40% of global oil production last year.

-

Energy1 month ago

Energy1 month agoHow Much Does the U.S. Depend on Russian Uranium?

Currently, Russia is the largest foreign supplier of nuclear power fuel to the U.S.

-

Uranium2 months ago

Uranium2 months agoCharted: Global Uranium Reserves, by Country

We visualize the distribution of the world’s uranium reserves by country, with 3 countries accounting for more than half of total reserves.

-

Energy3 months ago

Energy3 months agoVisualizing the Rise of the U.S. as Top Crude Oil Producer

Over the last decade, the United States has established itself as the world’s top producer of crude oil, surpassing Saudi Arabia and Russia.

-

Debt1 week ago

Debt1 week agoHow Debt-to-GDP Ratios Have Changed Since 2000

-

Markets2 weeks ago

Markets2 weeks agoRanked: The World’s Top Flight Routes, by Revenue

-

Countries2 weeks ago

Countries2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries

-

United States2 weeks ago

United States2 weeks agoWhere U.S. Inflation Hit the Hardest in March 2024

-

Green2 weeks ago

Green2 weeks agoTop Countries By Forest Growth Since 2001

-

United States2 weeks ago

United States2 weeks agoRanked: The Largest U.S. Corporations by Number of Employees