Technology

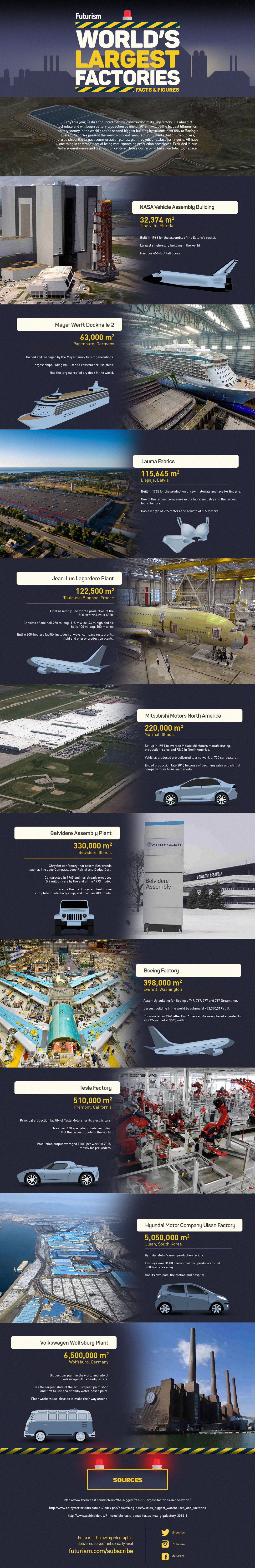

The World’s Largest Factories

The World’s Largest Factories

Where do our airplanes, vehicles, and spacecraft get built?

Like many other modern goods, they get made in manufacturing plants that are designed to produce at scale.

However, the factories pumping out the world’s cruise ships and electric cars are anything but ordinary. Most of them take up many city blocks, while a few of them have the size, workers, and amenities of an actual city.

From Hyundai’s Ulsan Factory in South Korea to the Boeing Factory near Seattle, today’s infographic and list from Futurism shows the world’s biggest factories. Many of the usual suspects can be found on this list such as Tesla or Airbus, but there is one outlier that may be surprising: one of the world’s largest factories is a 115,000 m² plant that produces lingerie lace in Latvia.

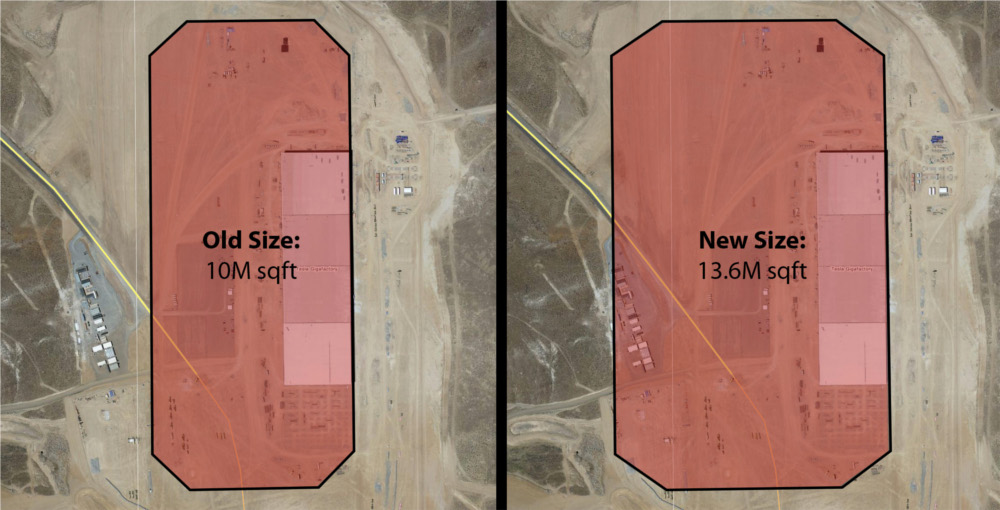

It’s also worth noting that Tesla’s Gigafactory 1 is not included on the list, because it isn’t opening until July 2016. Once completed, it is projected to dwarf many of the factories on this list at the impressive size of 1.3 million m² (13.6 million ft²) based off of the latest estimates:

That’s an expansion of roughly 40% from it’s previous expected size of 929,000 m² (10 million ft²).

Ranking The World’s Largest Factories

10. NASA Vehicle Assembly Building

Located in Florida, this 32,374 m² facility was built by NASA in 1966 for the assembly of the Saturn V rocket. It’s doors are 456 ft tall.

9. Meyer Werft Dockhalle 2

Owned and managed by the Meyer family for six generations, this is the largest shipbuilding hall used to construct cruise ships. It’s located in Papenburg, Germany, and is 63,000 m² in size.

8. Lauma Fabrics

An unexpected entry on this list, this factory produces raw materials and lace for lingerie. It’s about five football fields long, and two wide. Located in Latvia, the facility is 115,645 m² in total area.

7. Jean-Luc Lagardère Plant

It’s no surprise that aircraft assembly plants are among some of the world’s largest factories. This Airbus plant is in France, and is 122,500 m² in size.

6. Mitsubishi Motors North America

For automotive companies, size means economies of scale. This plant was set up in 1981 in Illinois to oversee Mitsubishi’s manufacturing, production, sales, and R&D in North America. This 220,000 m² facility ended production in late 2015 because of the company’s shift to focusing on Asian markets.

5. Belvidere Assembly Plant

Also located in Illinois, this factory is owned by Chrysler. It was constructed in 1965 and takes up a whopping 330,000 m² of space. It’s where the Jeep Compass, Jeep Patriot, and Dodge Dart get assembled.

4. Boeing Factory

Just outside of Seattle is the world’s biggest aircraft assembly operation by size. At 398,000 m², this is where the 747, 767, 777, and 787 Dreamliner get built. It’s also the largest building in the world by volume.

3. Tesla Factory

Not to be confused with the Gigafactory, this is Tesla’s current principal production facility for its cars. It uses 10 of the largest robots in the world, and has a 510,000 m² footprint in Fremont, California.

2. Hyundai Motor Company Ulsan Factory

This is 10x bigger than the Tesla Factory, located in South Korea. It’s over 5 million m² and is Hyundai’s main production facility. Amazingly, it employs 34,000 personnel, while having facilities often reserved for entire cities. The factory has its own hospital, port, and fire station.

1. Volkswagen Wolfsburg Plant

Weighing in at #1 on the “World’s Largest Factories” list is Volkswagen’s plant in Wolfsburg, Germany. It edges out Hyundai’s entry by about 1.5 million m². It’s the biggest car plant in the world and also Volkswagen AG’s headquarters. It’s so big, at 6.5 million m², that floor workers use bicycles to get around.

Technology

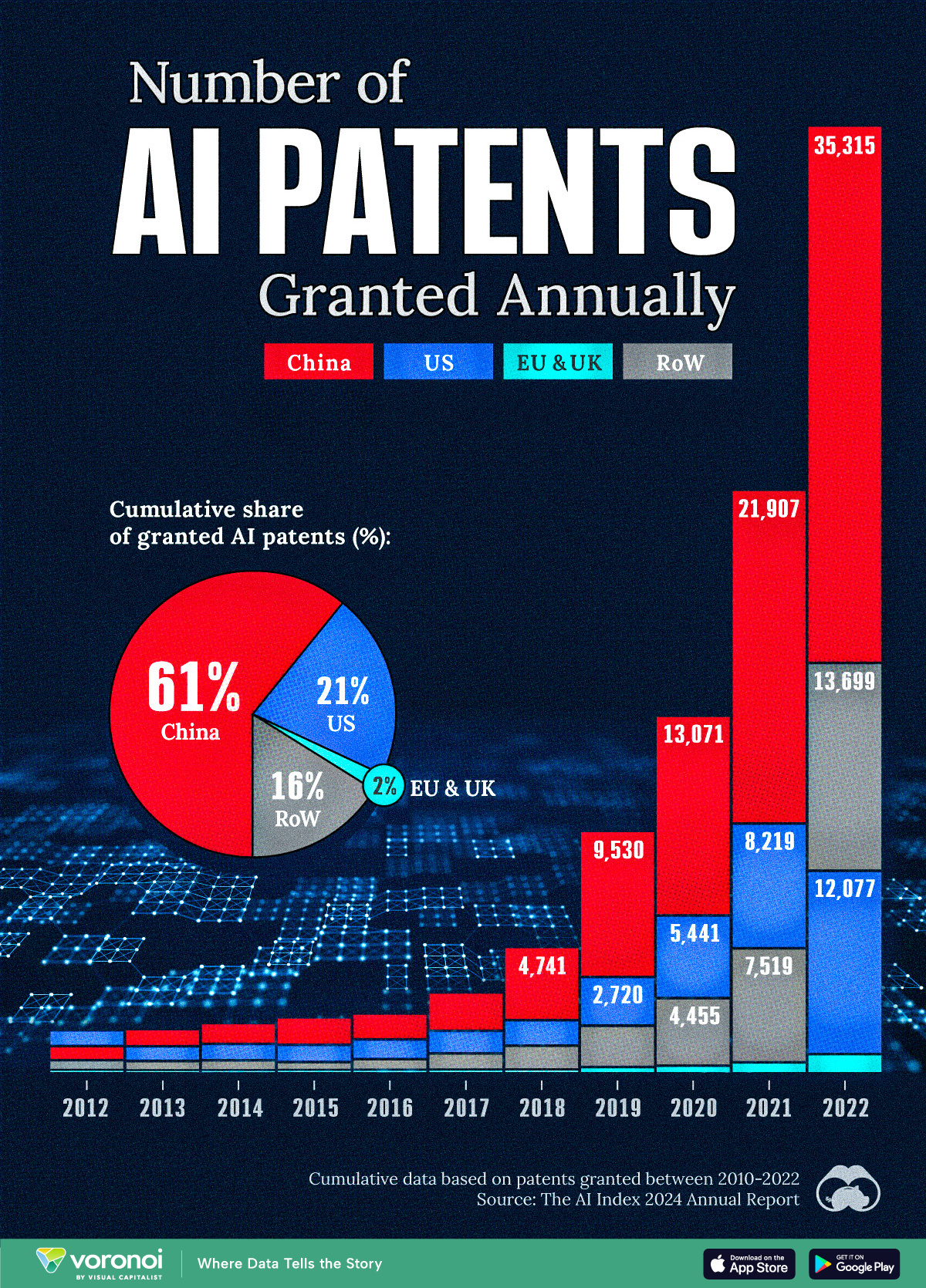

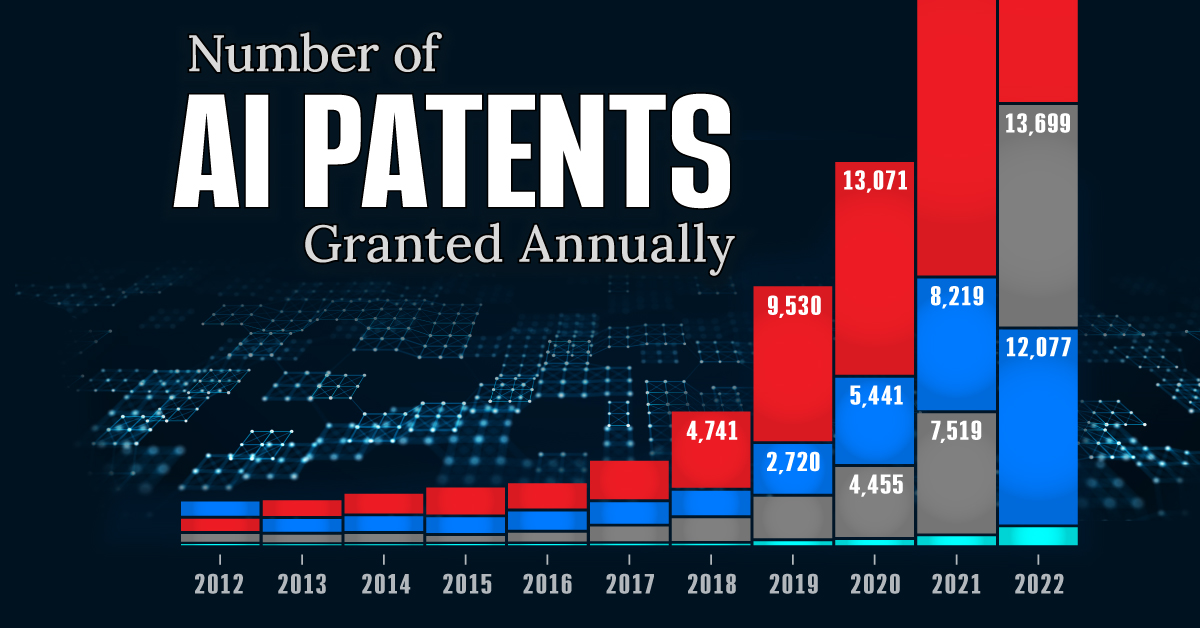

Visualizing AI Patents by Country

See which countries have been granted the most AI patents each year, from 2012 to 2022.

Visualizing AI Patents by Country

This was originally posted on our Voronoi app. Download the app for free on iOS or Android and discover incredible data-driven charts from a variety of trusted sources.

This infographic shows the number of AI-related patents granted each year from 2010 to 2022 (latest data available). These figures come from the Center for Security and Emerging Technology (CSET), accessed via Stanford University’s 2024 AI Index Report.

From this data, we can see that China first overtook the U.S. in 2013. Since then, the country has seen enormous growth in the number of AI patents granted each year.

| Year | China | EU and UK | U.S. | RoW | Global Total |

|---|---|---|---|---|---|

| 2010 | 307 | 137 | 984 | 571 | 1,999 |

| 2011 | 516 | 129 | 980 | 581 | 2,206 |

| 2012 | 926 | 112 | 950 | 660 | 2,648 |

| 2013 | 1,035 | 91 | 970 | 627 | 2,723 |

| 2014 | 1,278 | 97 | 1,078 | 667 | 3,120 |

| 2015 | 1,721 | 110 | 1,135 | 539 | 3,505 |

| 2016 | 1,621 | 128 | 1,298 | 714 | 3,761 |

| 2017 | 2,428 | 144 | 1,489 | 1,075 | 5,136 |

| 2018 | 4,741 | 155 | 1,674 | 1,574 | 8,144 |

| 2019 | 9,530 | 322 | 3,211 | 2,720 | 15,783 |

| 2020 | 13,071 | 406 | 5,441 | 4,455 | 23,373 |

| 2021 | 21,907 | 623 | 8,219 | 7,519 | 38,268 |

| 2022 | 35,315 | 1,173 | 12,077 | 13,699 | 62,264 |

In 2022, China was granted more patents than every other country combined.

While this suggests that the country is very active in researching the field of artificial intelligence, it doesn’t necessarily mean that China is the farthest in terms of capability.

Key Facts About AI Patents

According to CSET, AI patents relate to mathematical relationships and algorithms, which are considered abstract ideas under patent law. They can also have different meaning, depending on where they are filed.

In the U.S., AI patenting is concentrated amongst large companies including IBM, Microsoft, and Google. On the other hand, AI patenting in China is more distributed across government organizations, universities, and tech firms (e.g. Tencent).

In terms of focus area, China’s patents are typically related to computer vision, a field of AI that enables computers and systems to interpret visual data and inputs. Meanwhile America’s efforts are more evenly distributed across research fields.

Learn More About AI From Visual Capitalist

If you want to see more data visualizations on artificial intelligence, check out this graphic that shows which job departments will be impacted by AI the most.

-

Mining1 week ago

Mining1 week agoGold vs. S&P 500: Which Has Grown More Over Five Years?

-

Markets2 weeks ago

Markets2 weeks agoRanked: The Most Valuable Housing Markets in America

-

Money2 weeks ago

Money2 weeks agoWhich States Have the Highest Minimum Wage in America?

-

AI2 weeks ago

AI2 weeks agoRanked: Semiconductor Companies by Industry Revenue Share

-

Markets2 weeks ago

Markets2 weeks agoRanked: The World’s Top Flight Routes, by Revenue

-

Countries2 weeks ago

Countries2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries