Oil and Gas

How Much Oil is in an Electric Vehicle?

How Much Oil is in an Electric Vehicle?

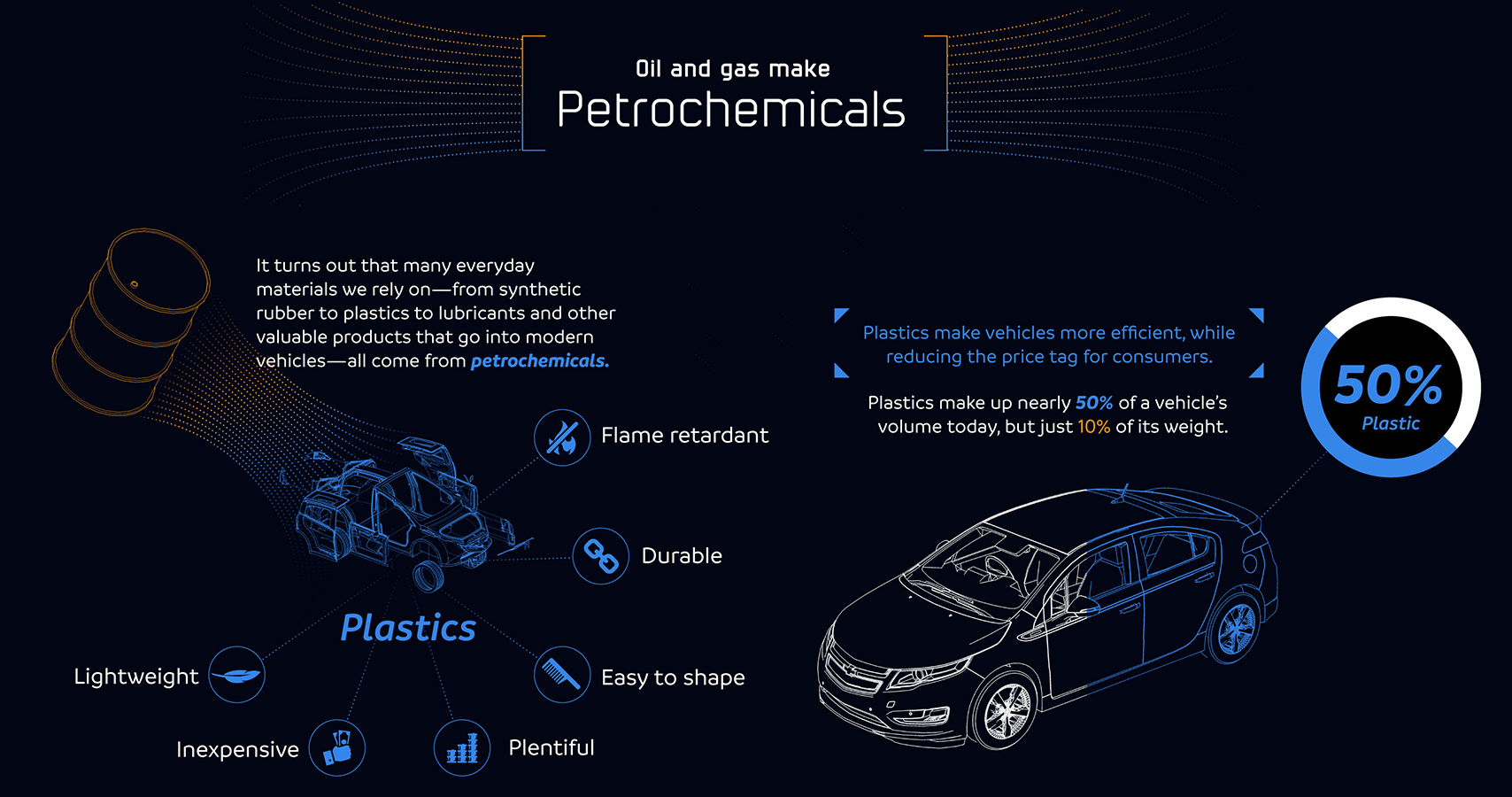

When most people think about oil and natural gas, the first thing that comes to mind is the gas in the tank of their car. But there is actually much more to oil’s role, than meets the eye…

Oil, along with natural gas, has hundreds of different uses in a modern vehicle through petrochemicals.

Today’s infographic comes to us from American Fuel & Petrochemicals Manufacturers, and covers why oil is a critical material in making the EV revolution possible.

Pliable Properties

It turns out the many everyday materials we rely on from synthetic rubber to plastics to lubricants all come from petrochemicals.

The use of various polymers and plastics has several advantages for manufacturers and consumers:

- Lightweight

- Inexpensive

- Plentiful

- Easy to Shape

- Durable

- Flame Retardant

Today, plastics can make up to 50% of a vehicle’s volume but only 10% of its weight. These plastics can be as strong as steel, but light enough to save on fuel and still maintain structural integrity.

This was not always the case, as oil’s use has evolved and grown over time.

Not Your Granddaddy’s Caddy

Plastics were not always a critical material in auto manufacturing industry, but over time plastics such as polypropylene and polyurethane became indispensable in the production of cars.

Rolls Royce was one of the first car manufacturers to boast about the use of plastics in its car interior. Over time, plastics have evolved into a critical material for reducing the overall weight of vehicles, allowing for more power and conveniences.

Timeline:

- 1916

Rolls Royce uses phenol formaldehyde resin in its car interiors - 1941

Henry Ford experiments with an “all-plastic” car - 1960

About 20 lbs. of plastics is used in the average car - 1970

Manufacturers begin using plastic for interior decorations - 1980

Headlights, bumpers, fenders and tailgates become plastic - 2000

Engineered polymers first appear in semi-structural parts of the vehicle - Present

The average car uses over 1000 plastic parts

Electric Dreams: Petrochemicals for EV Innovation

Plastics and other materials made using petrochemicals make vehicles more efficient by reducing a vehicle’s weight, and this comes at a very reasonable cost.

For every 10% in weight reduction, the fuel economy of a car improves roughly 5% to 7%. EV’s need to achieve weight reductions because the battery packs that power them can weigh over 1000 lbs, requiring more power.

Today, plastics and polymers are used for hundreds of individual parts in an electric vehicle.

Oil and the EV Future

Oil is most known as a source of fuel, but petrochemicals also have many other useful physical properties.

In fact, petrochemicals will play a critical role in the mass adoption of electric vehicles by reducing their weight and improving their ranges and efficiency. In According to IHS Chemical, the average car will use 775 lbs of plastic by 2020.

Although it seems counterintuitive, petrochemicals derived from oil and natural gas make the major advancements by today’s EVs possible – and the continued use of petrochemicals will mean that both EVS and traditional vehicles will become even lighter, faster, and more efficient.

Commodities

Charted: What’s Driving the U.S. Trade Deficit?

This graphic the U.S. trade deficit growth since 1990, and how manufactured goods and fuels factor in over the last three decades.

How Manufactured Goods Dominate the U.S. Trade Deficit

The United States has had many major trading partners over the decades, with annual imports and exports from them both totaling trillions of dollars.

Ever since the 1970s, the country’s imports started to overshadow exports and the U.S. trade deficit began to grow. Once the 1990s began, fueled by globalization-friendly policies around the world and cheap international goods, the trade deficit began to climb even more rapidly.

In this graphic, Ehsan Soltani uses data from the World Trade Organization to highlight the role of manufactured goods in the rising U.S. trade deficit over the last three decades.

U.S. Trade Deficit in Goods From 1990 to 2022

In 2022, the U.S. trade deficit for goods hit $1.31 trillion, consisting of more than $3 trillion in imports and offset by $2 trillion in exports. That’s a growth of 40% over a decade from a deficit $791 billion in 2012.

| Year | U.S. Exports (Total) | U.S. Imports (Total) | Trade Surplus/Deficit |

|---|---|---|---|

| 2022 | $2,065B | $3,376B | -$1,311B |

| 2021 | $1,754B | $2,935B | -$1,183B |

| 2020 | $1,425B | $2,407B | -$982B |

| 2019 | $1,643B | $2,567B | -$924B |

| 2018 | $1,664B | $2,614B | -$950B |

| 2017 | $1,546B | $2,408B | -$862B |

| 2016 | $1,451B | $2,250B | -$799B |

| 2015 | $1,503B | $2,315B | -$813B |

| 2014 | $1,621B | $2,413B | -$792B |

| 2013 | $1,580B | $2,329B | -$749B |

| 2012 | $1,546B | $2,337B | -$791B |

| 2011 | $1,483B | $2,266B | -$784B |

| 2010 | $1,278B | $1,969B | -$691B |

| 2009 | $1,056B | $1,605B | -$549B |

| 2008 | $1,287B | $2,169B | -$882B |

| 2007 | $1,148B | $2,020B | -$872B |

| 2006 | $1,026B | $1,918B | -$892B |

| 2005 | $901B | $1,733B | -$832B |

| 2004 | $815B | $1,526B | -$711B |

| 2003 | $725B | $1,303B | -$578B |

| 2002 | $693B | $1,200B | -$507B |

| 2001 | $729B | $1,179B | -$450B |

| 2000 | $782B | $1,259B | -$477B |

| 1999 | $696B | $1,059B | -$364B |

| 1998 | $682B | $944B | -$262B |

| 1997 | $689B | $899B | -$210B |

| 1996 | $625B | $822B | -$197B |

| 1995 | $585B | $771B | -$186B |

| 1994 | $513B | $689B | -$177B |

| 1993 | $465B | $603B | -$139B |

| 1992 | $448B | $554B | -$106B |

| 1991 | $422B | $508B | -$87B |

| 1990 | $394B | $517B | -$123B |

When compared to trade numbers from the early 1990s and 2000s, its clear how much U.S. trade as a whole has grown.

In 1992, the U.S. trade deficit for goods sat at only $106 billion, with imports totaling $554 billion and exports totaling $448 billion. Just a decade later by 2002, the deficit had already climbed by five times.

Manufactured Goods Trade Outshines Fuel

Analyzing the subtleties in the country’s deficit in traded goods also shows how U.S. reliance on other countries has changed over the years.

In 1990, the deficit incurred from trading manufactured goods—which doesn’t include fuel, mining production, agricultural products, or services—contributed to 69% of the total U.S. goods trade deficit.

| Year | U.S. Exports (Manufactured) | U.S. Imports (Manufactured) | Trade Surplus/Deficit |

|---|---|---|---|

| 2022 | $1,196B | $2,569B | -$1,372B |

| 2021 | $1,079B | $2,256B | -$1,177B |

| 2020 | $915B | $1,892B | -$976B |

| 2019 | $1,036B | $1,994B | -$958B |

| 2018 | $1,050B | $2,016B | -$966B |

| 2017 | $1,008B | $1,872B | -$864B |

| 2016 | $969B | $1,775B | -$806B |

| 2015 | $1,008B | $1,811B | -$803B |

| 2014 | $1,052B | $1,752B | -$700B |

| 2013 | $1,020B | $1,650B | -$629B |

| 2012 | $1,009B | $1,619B | -$610B |

| 2011 | $969B | $1,524B | -$555B |

| 2010 | $872B | $1,369B | -$497B |

| 2009 | $725B | $1,122B | -$397B |

| 2008 | $973B | $1,417B | -$443B |

| 2007 | $909B | $1,409B | -$500B |

| 2006 | $829B | $1,350B | -$522B |

| 2005 | $674B | $1,238B | -$564B |

| 2004 | $618B | $1,134B | -$516B |

| 2003 | $589B | $990B | -$401B |

| 2002 | $571B | $934B | -$363B |

| 2001 | $602B | $906B | -$303B |

| 2000 | $646B | $968B | -$322B |

| 1999 | $575B | $843B | -$268B |

| 1998 | $558B | $758B | -$199B |

| 1997 | $553B | $699B | -$145B |

| 1996 | $485B | $634B | -$150B |

| 1995 | $450B | $608B | -$158B |

| 1994 | $399B | $540B | -$141B |

| 1993 | $356B | $465B | -$109B |

| 1992 | $340B | $420B | -$79B |

| 1991 | $319B | $380B | -$61B |

| 1990 | $290B | $376B | -$85B |

Since then, despite the country exporting billions of dollars of products, the deficit caused by imported manufactured goods has only grown. In 2021, it crossed $1 trillion in deficit alone.

Part of that growth is directly tied to increasing imports from China over the 21st century. From 2001 to 2018, China’s exports to the U.S. accounted for 59% of the latter’s increasing manufacturing trade deficit, ranging in goods from electronics to machinery.

However, the U.S. managed to recover some of this deficit through surplus fuel exports, which have been increasing over the same time period.

| Year | Fuel Exports | Fuel Imports | Fuel Surplus/Deficit |

|---|---|---|---|

| 2022 | $378B | $323B | $56B |

| 2021 | $240B | $224B | $16B |

| 2020 | $155B | $130B | $25B |

| 2019 | $200B | $210B | $-10B |

| 2018 | $193B | $242B | $-49B |

| 2017 | $139B | $204B | $-65B |

| 2016 | $94B | $163B | $-69B |

| 2015 | $104B | $200B | $-96B |

| 2014 | $155B | $358B | $-203B |

| 2013 | $149B | $389B | $-240B |

| 2012 | $137B | $433B | $-295B |

| 2011 | $130B | $463B | $-332B |

| 2010 | $81B | $364B | $-283B |

| 2009 | $55B | $279B | $-224B |

| 2008 | $77B | $502B | $-425B |

| 2007 | $42B | $372B | $-330B |

| 2006 | $35B | $345B | $-310B |

| 2005 | $27B | $301B | $-275B |

| 2004 | $19B | $217B | $-198B |

| 2003 | $14B | $163B | $-149B |

| 2002 | $12B | $122B | $-110B |

| 2001 | $13B | $129B | $-116B |

| 2000 | $13B | $140B | $-126B |

| 1999 | $10B | $79B | $-69B |

| 1998 | $10B | $62B | $-52B |

| 1997 | $13B | $83B | $-70B |

| 1996 | $12B | $77B | $-65B |

| 1995 | $10B | $63B | $-53B |

| 1994 | $9B | $60B | $-51B |

| 1993 | $10B | $59B | $-49B |

| 1992 | $11B | $59B | $-47B |

| 1991 | $12B | $58B | $-46B |

| 1990 | $12B | $69B | $-56B |

Historically the U.S. was a larger fuel consumer than producer, and was heavily affected by soaring oil prices from 2003 to the Great Recession. In 2008, the United States trade deficit in fuel hit $425 billion.

But a boom in shale oil production has seen the country rapidly increase production and exports, becoming the world’s largest crude oil producer. Despite falling oil prices, by 2020 the U.S. managed to erase its fuel trade deficit.

Will The U.S. Trade Deficit Keep Growing?

The dominance of manufactured goods in the U.S. trade deficit poses a significant challenge for policymakers and businesses.

On one hand, the country’s reliance on other countries for cheaper parts and labor has allowed its economy to benefit. But it has also become increasingly susceptible to tariffs, slowdowns in other countries, and trade wars.

While there are efforts in place to promote domestic manufacturing, such as in semiconductor chips, the effects have yet to dent the goods trade deficit.

-

Mining1 week ago

Mining1 week agoGold vs. S&P 500: Which Has Grown More Over Five Years?

-

Markets2 weeks ago

Markets2 weeks agoRanked: The Most Valuable Housing Markets in America

-

Money2 weeks ago

Money2 weeks agoWhich States Have the Highest Minimum Wage in America?

-

AI2 weeks ago

AI2 weeks agoRanked: Semiconductor Companies by Industry Revenue Share

-

Markets2 weeks ago

Markets2 weeks agoRanked: The World’s Top Flight Routes, by Revenue

-

Countries2 weeks ago

Countries2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries

Creator Program

Creator Program