Life Cycle of a Mine: From Planning to Rehabilitation

The following content is sponsored by Natural Resources Canada.

Life Cycle of a Mine: From Planning to Rehabilitation

View the full-size infographic by clicking here.

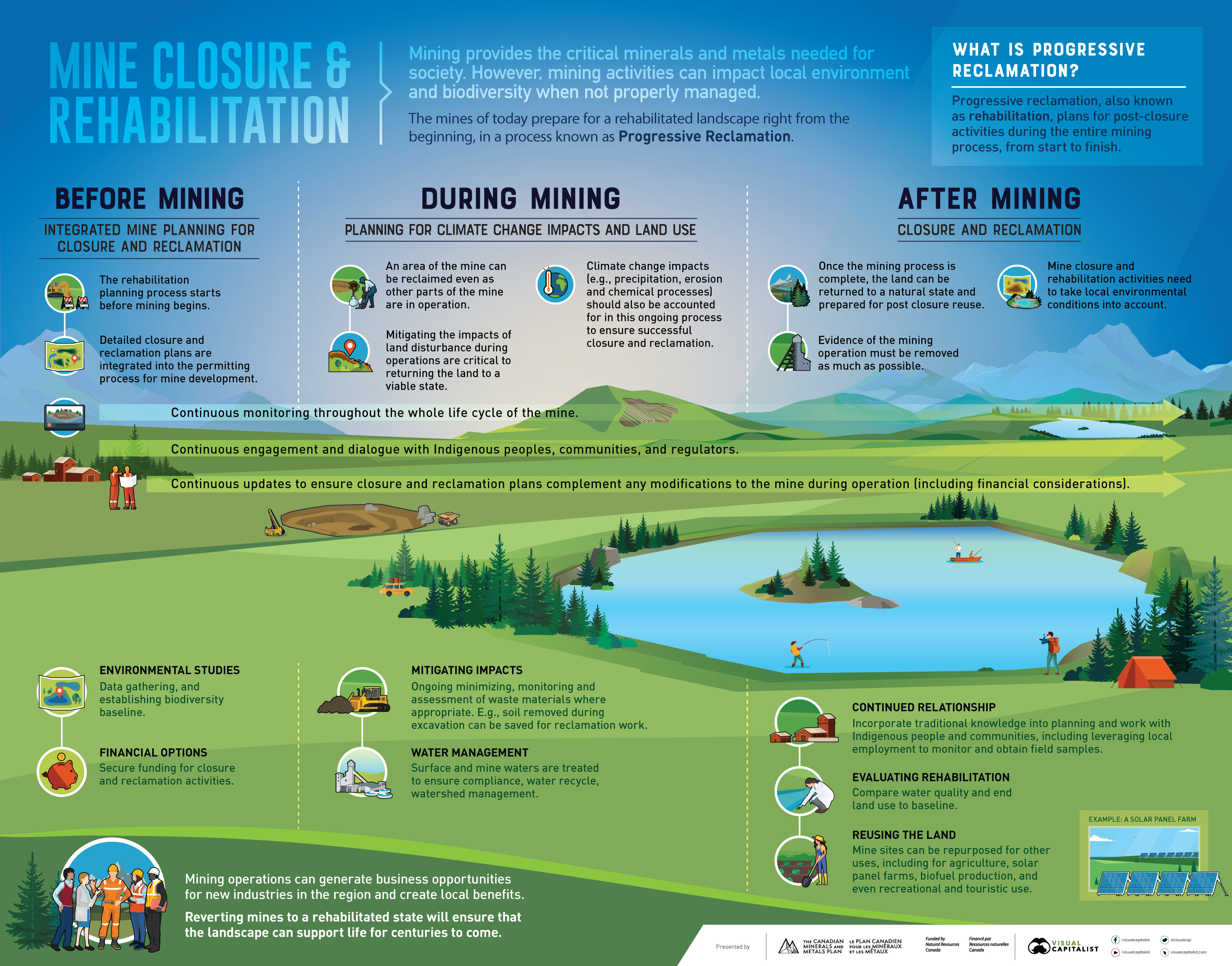

Mining provides the critical minerals and metals needed for modern society to function. However, if these resources are not properly managed, mining activity can impact local environments and biodiversity.

For this reason, the mines of today prepare for a rehabilitated landscape right from the beginning, in a process known as “progressive reclamation”.

Today’s infographic comes to us from Natural Resources Canada, a government entity which funded the development of the Canadian Minerals and Metals Plan that supports sustainable mining practices throughout its lifecycle.

What is Progressive Mine Reclamation?

The process of progressive reclamation, also known as rehabilitation, plans for post-closure activities during the mining process, from before the first bit of dirt is moved to when the last truck leaves the mine.

There are three stages to the mining process, each with their own associated activities to plan for mine reclamation.

- Before Mining: Integrated mine planning for closure and reclamation

- During Mining: Planning for climate change impacts and land use

- After Mining: Closure and reclamation

While these are distinct stages, three continuous processes occur throughout the sequence of the mining life cycle:

- Continuous monitoring

- Continuous engagement with Indigenous Peoples, communities, and regulators

- Continuous updates to ensure closure and reclamation plans complement any modifications to the mine plan

- Agriculture

- Solar panel farms

- Biofuel production

- Recreational and tourist use

Each process is meant to be inclusive, continuous, and responsive to the constantly changing environment to ensure there is flexibility and preparedness to adapt as necessary.

1. Before Mining

The rehabilitation process starts before mining begins. The permitting process for mine development requires closure and reclamation plans.

2. During Mining

An area of the mine can be reclaimed even as other parts of the mine are in operation. Mitigating the impacts of land disturbance during operations are critical to return the land to a viable state.

Climate change impacts can affect operations, and mine operators should account for this in ongoing processes to ensure successful closure and reclamation.

Water treatment facilities process surface and mine waters to ensure compliance, water recycling, and watershed management. This is all under the eye of continuous monitoring of the movement of earth and materials.

3. After Mining

Once the mining process is complete, mining companies can return the land to a natural state and prepare for post-closure reuse. Mine closure and rehabilitation activities need to take local environmental conditions into account. Evidence of the mining operation must be removed as much as possible.

Part of this process means the continued relationship with the people, community, and lands affected. Mining companies can re-purpose for other uses, including:

By incorporating local and traditional knowledge into planning and working with Indigenous Peoples and communities, modern practices and local knowledge can restore the land in a way that also brings benefits to the local community.

The Canadian Minerals and Metals Plan

Mining operations can generate opportunities for new businesses to create local benefits. Reverting mines to a rehabilitated state will ensure that the landscape can continue to support life for centuries to come.

The Canadian Minerals and Metals Plan supports this vision of progressive mine rehabilitation, to ensure Canada remains a responsible mining powerhouse for generations to come.

-

Sponsored3 years ago

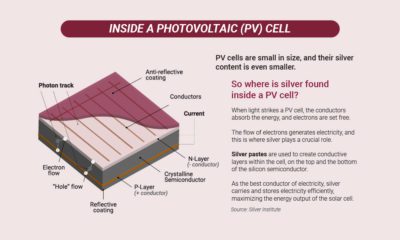

Sponsored3 years agoMore Than Precious: Silver’s Role in the New Energy Era (Part 3 of 3)

Long known as a precious metal, silver in solar and EV technologies will redefine its role and importance to a greener economy.

-

Sponsored7 years ago

Sponsored7 years agoThe History and Evolution of the Video Games Market

Everything from Pong to the rise of mobile gaming and AR/VR. Learn about the $100 billion video games market in this giant infographic.

-

Sponsored8 years ago

Sponsored8 years agoThe Extraordinary Raw Materials in an iPhone 6s

Over 700 million iPhones have now been sold, but the iPhone would not exist if it were not for the raw materials that make the technology...

-

Sponsored9 years ago

Sponsored9 years agoThe Industrial Internet, and How It’s Revolutionizing Mining

The convergence of the global industrial sector with big data and the internet of things, or the Industrial Internet, will revolutionize how mining works.