Mining

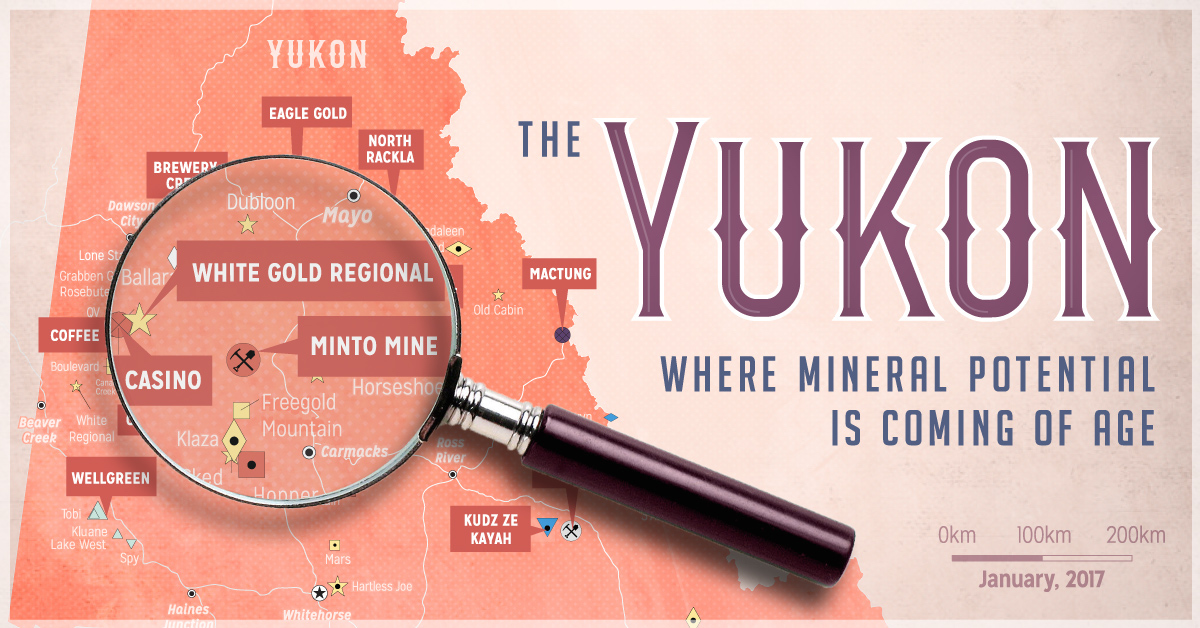

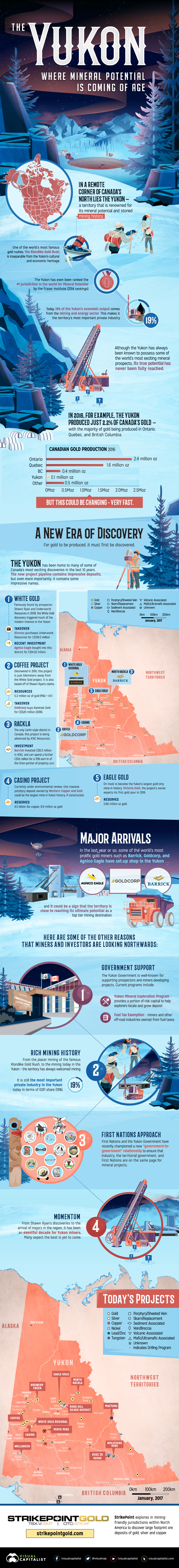

The Yukon: Where Mineral Potential is Coming of Age

In a remote corner of Canada’s north lies the Yukon – a territory that is renowned for both its legendary mineral potential and its storied mining history.

But while the Yukon only produced 2.2% of Canada’s gold in 2016, the territory’s considerable potential may finally be getting realized in a big way. In the last few years, globally significant discoveries have been made, and now mining giants such as Barrick, Goldcorp, and Agnico Eagle are making their move into the Yukon to get in on the action.

A Coming of Age Story

Today’s infographic comes from Strikepoint Gold, and it showcases some of the reasons on why the most important chapter in the Yukon’s mining story may just be beginning.

Although the Yukon has been known to possess incredible mineral potential for a long time, it is only in the last few years that signs have been pointing towards this being realized in the form of globally significant discoveries, investment from major players, and mines being built.

A New Era in the Yukon

For gold to be produced, it must first be discovered.

The Yukon has been home to many of some of Canada’s most exciting discoveries in the last 10 years. The new project pipeline contains impressive deposits, but even more importantly – it contains some impressive names.

White Gold

Famously found by prospector Shawn Ryan and Underworld Resources in 2008, the White Gold discovery triggered much of the modern interest in the Yukon. Kinross purchased Underworld Resources for C$139.2 million at the height of the gold market. More recently, major Agnico Eagle has bought into the district for C$14.52 million.

Coffee Project

Discovered in 2010, this project is just kilometers away from the White Gold project. It too is based off of Shawn Ryan’s claims. Most recently, Goldcorp bought the project for C$520 million through its acquisition of Kaminak Gold. It currently has 5.2 million oz of gold (M&I + Inf.) in resources.

Casino Project

Currently under environmental review, this massive porphyry deposit owned by Western Copper and Gold could be the largest mine in Yukon history, if constructed. Right now, the deposit has reserves of 4.5 billion lbs of copper, and 8.9 million oz of gold.

Rackla

The only Carlin-style district in Canada, this project is being advanced by ATAC Resources. Recently, ATAC Resources generated headlines with an investment from major Barrick Gold, who put in C$8.3 million while also committing up to a further C$55 million to earn-in 70% of the property’s Orion project.

Eagle Gold

Eagle Gold is on track to become the Yukon’s largest gold-only mine in history. Victoria Gold, the project’s owner, expects its first gold pour in 2019. Currently the mine has 2.66 million oz of gold in reserves.

Major Arrivals

In the last year or so, some of the world’s most prolific gold miners such as Barrick, Goldcorp, and Agnico Eagle have set up shop in the Yukon – and it could be a sign that the territory is close to reaching its ultimate potential as a top tier mining destination.

Here are some of the other reasons that miners and investors are looking northwards:

1. Government Support

The Yukon Government is well-known for supporting prospectors and miners developing projects. Current programs include the Yukon Mineral Exploration Program, which provides a portion of risk capital to help explorers locate and grow deposits, as well as the Fuel Tax Exemption, which makes miners and other off-road industries exempt from fuel taxes.

2. A Rich Mining History

From the placer mining of the famous Klondike Gold Rush, to the mining today in the Yukon – the territory has always welcomed mining. In fact, mining is still the most important private industry today in the Yukon by GDP share (19%).

3. First Nations Approach

First Nations and the Yukon Government have recently championed a new “government-to-government” relationship to ensure that industry, the territorial government, and First Nations are on the same page for mineral projects.

4. Momentum

From Shawn Ryan’s discoveries to the arrival of majors in the region, it has been an eventful decade for Yukon miners. Many expect the best is yet to come.

Copper

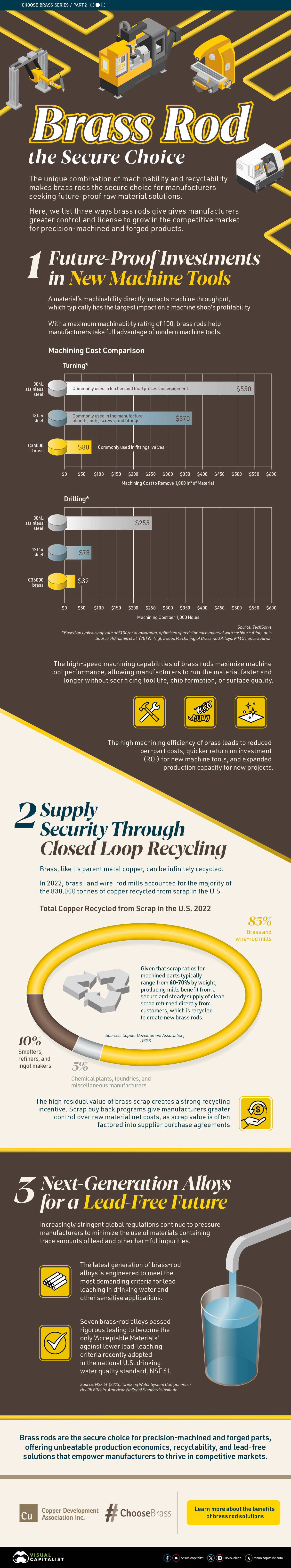

Brass Rods: The Secure Choice

This graphic shows why brass rods are the secure choice for precision-machined and forged parts.

Brass Rods: The Secure Choice

The unique combination of machinability and recyclability makes brass rods the secure choice for manufacturers seeking future-proof raw material solutions.

This infographic, from the Copper Development Association, shows three ways brass rods give manufacturers greater control and a license to grow in the competitive market for precision-machined and forged products.

Future-Proof Investments in New Machine Tools

A material’s machinability directly impacts machine throughput, which typically has the largest impact on machine shop profitability.

The high-speed machining capabilities of brass rods maximize machine tool performance, allowing manufacturers to run the material faster and longer without sacrificing tool life, chip formation, or surface quality.

The high machining efficiency of brass leads to reduced per-part costs, quicker return on investment (ROI) for new machine tools, and expanded production capacity for new projects.

Supply Security Through Closed Loop Recycling

Brass, like its parent element copper, can be infinitely recycled.

In 2022, brass- and wire-rod mills accounted for the majority of the 830,000 tonnes of copper recycled from scrap in the United States.

Given that scrap ratios for machined parts typically range from 60-70% by weight, producing mills benefit from a secure and steady supply of clean scrap returned directly from customers, which is recycled to create new brass rods.

The high residual value of brass scrap creates a strong recycling incentive. Scrap buy back programs give manufacturers greater control over raw material net costs as scrap value is often factored into supplier purchase agreements.

Next Generation Alloys for a Lead-Free Future

Increasingly stringent global regulations continue to pressure manufacturers to minimize the use of materials containing trace amounts of lead and other harmful impurities.

The latest generation of brass-rod alloys is engineered to meet the most demanding criteria for lead leaching in drinking water and other sensitive applications.

Seven brass-rod alloys passed rigorous testing to become the only ‘Acceptable Materials’ against lower lead leaching criteria recently adopted in the national U.S. drinking water quality standard, NSF 61.

Learn more about the advantages of brass rods solutions.

-

Base Metals1 year ago

Base Metals1 year agoRanked: The World’s Largest Copper Producers

Many new technologies critical to the energy transition rely on copper. Here are the world’s largest copper producers.

-

Silver2 years ago

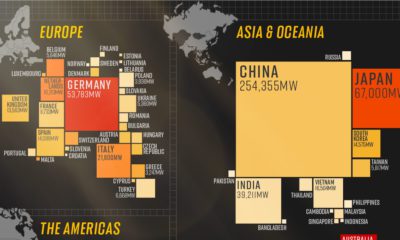

Silver2 years agoMapped: Solar Power by Country in 2021

In 2020, solar power saw its largest-ever annual capacity expansion at 127 gigawatts. Here’s a snapshot of solar power capacity by country.

-

Batteries5 years ago

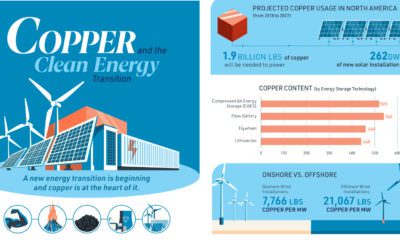

Batteries5 years agoVisualizing Copper’s Role in the Transition to Clean Energy

A clean energy transition is underway as wind, solar, and batteries take center stage. Here’s how copper plays the critical role in these technologies.

-

Science5 years ago

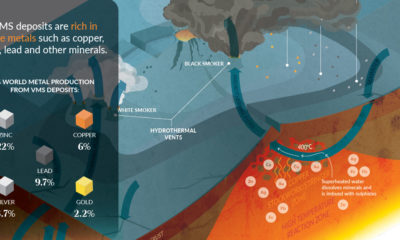

Science5 years agoEverything You Need to Know on VMS Deposits

Deep below the ocean’s waves, VMS deposits spew out massive amounts of minerals like copper, zinc, and gold, making them a key source of the metals…

-

Copper5 years ago

Copper5 years agoHow Much Copper is in an Electric Vehicle?

Have you ever wondered how much copper is in an electric vehicle? This infographic shows the metal’s properties as well as the quantity of copper used.

-

Copper6 years ago

Copper6 years agoCopper: Driving the Green Energy Revolution

Renewable energy is set to fuel a new era of copper demand – here’s how much copper is used in green applications from EVs to photovoltaics.

-

Maps2 weeks ago

Maps2 weeks agoMapped: Average Wages Across Europe

-

Money1 week ago

Money1 week agoWhich States Have the Highest Minimum Wage in America?

-

Real Estate1 week ago

Real Estate1 week agoRanked: The Most Valuable Housing Markets in America

-

Markets1 week ago

Markets1 week agoCharted: Big Four Market Share by S&P 500 Audits

-

AI1 week ago

AI1 week agoThe Stock Performance of U.S. Chipmakers So Far in 2024

-

Automotive1 week ago

Automotive1 week agoAlmost Every EV Stock is Down After Q1 2024

-

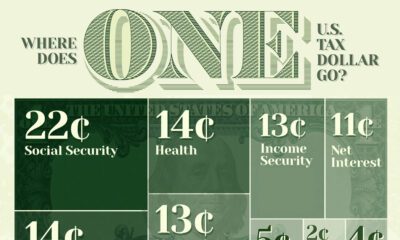

Money2 weeks ago

Money2 weeks agoWhere Does One U.S. Tax Dollar Go?

-

Green2 weeks ago

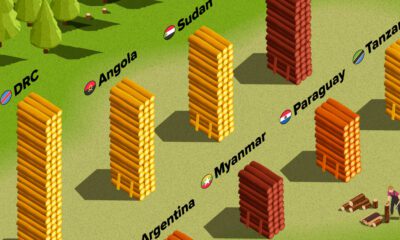

Green2 weeks agoRanked: Top Countries by Total Forest Loss Since 2001