Titanium: The Metal of the Future

Titanium: The Metal of the Future

Titanium is a popular metal, but are we harnessing its true potential or merely scratching the surface?

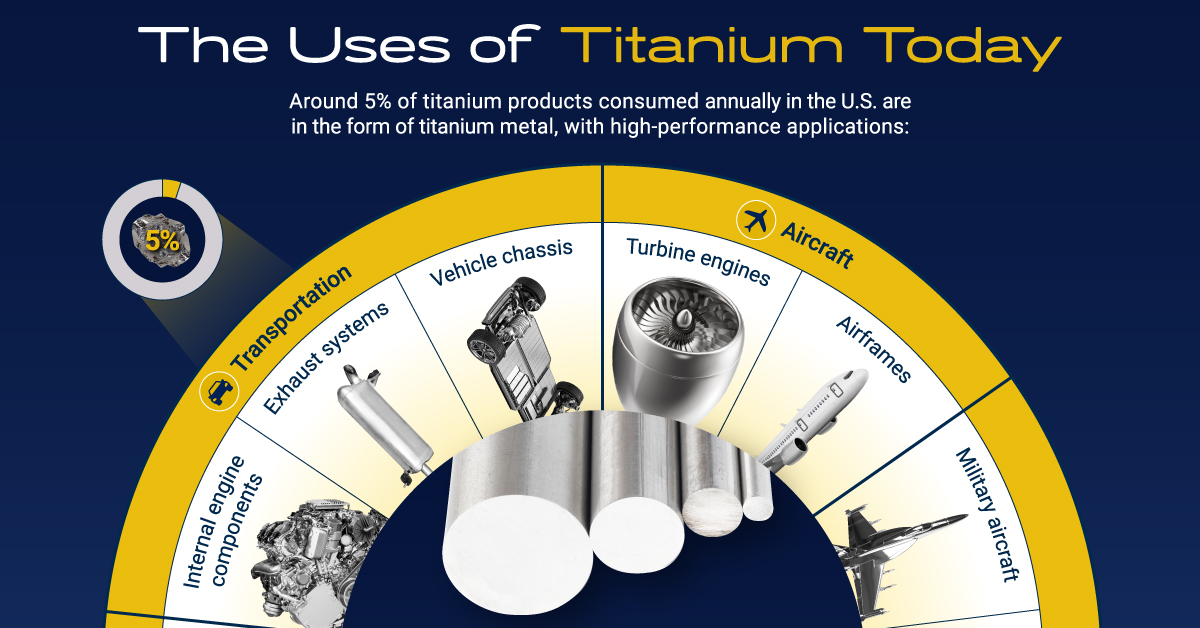

Despite having superior properties when compared to stainless steel and aluminum, titanium is produced and used on a relatively small scale. Its current applications are highly specialized, ranging from aircraft turbine engines to medical implants and military vehicles.

This infographic sponsored by IperionX explores titanium’s growth markets and potential for mainstream application in the future.

Titanium Production vs. Stainless Steel and Aluminum

Titanium’s high cost limits its applications and scale of production.

In fact, global titanium metal production is less than 1% of aluminum and steel production.

| Metal | 2023 production (million tonnes) | Price range per tonne |

|---|---|---|

| Aluminum | 68.9Mt | $2.4K |

| Stainless steel | 41.9Mt | $3-4K |

| Titanium metal | 0.3Mt | $13-16K |

Titanium is expensive because it is still processed and refined using the 80-year-old Kroll process. Invented by metallurgist William Kroll in 1940, the Kroll process is complex, energy-intensive, and carbon-intensive.

While titanium produced using the Kroll process is uneconomical for large-scale uses, cost-competitive and sustainably-produced titanium could kickstart a new Titanium Age.

The Growth Markets for Titanium

Titanium has untapped growth potential in many markets, but four industries stand out:

- Aerospace:

Titanium’s high strength-to-weight ratio and high melting point make it a critical material for aerospace and space exploration. The global space economy is growing exponentially, with space industry revenues projected to surpass $1 trillion by 2040 according to Morgan Stanley.

- Consumer Electronics:

In high-end consumer electronics like laptops and smartphones, titanium allows for stronger, lighter, and thinner products.

- Electric Vehicles:

Titanium’s properties allow the potential to significantly reduce the weight of EVs, improving battery efficiency and range. Tesla’s Model S uses a titanium underbody shield to protect the car from roadside damage, thanks to the metal’s exceptional strength-to-weight ratio. - Luxury Goods:

Titanium’s durability and anti-corrosive properties make it an increasingly demanded premium product for luxury goods, including watches.

Dawn of the Titanium Age

Titanium is as strong as steel and 45% lighter, and twice as strong as aluminum. However, it has not achieved its potential because of high production costs.

With cost-competitive production, titanium has the potential to substitute stainless steel and aluminum, making many products stronger and/or lighter.

IperionX is a U.S. metals technology company developing the world’s first 100% recycled, low-cost, low-carbon titanium supply chain. Click here to learn more now.

In part 3 of the Titanium 101 Series, we will dive into foreign dominance of the titanium supply chain and the need to onshore production in the United States.

-

Lithium2 days ago

Lithium2 days agoRanked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

-

Mining1 week ago

Mining1 week agoGold vs. S&P 500: Which Has Grown More Over Five Years?

The price of gold has set record highs in 2024, but how has this precious metal performed relative to the S&P 500?

-

Mining3 weeks ago

Mining3 weeks agoCharted: The Value Gap Between the Gold Price and Gold Miners

While the price of gold has reached new record highs in 2024, gold mining stocks are still far from their 2011 peaks.

-

Uranium2 months ago

Uranium2 months agoCharted: Global Uranium Reserves, by Country

We visualize the distribution of the world’s uranium reserves by country, with 3 countries accounting for more than half of total reserves.

-

Energy4 months ago

Energy4 months agoThe Periodic Table of Commodity Returns (2014-2023)

Commodity returns in 2023 took a hit. This graphic shows the performance of commodities like gold, oil, nickel, and corn over the last decade.

-

Mining4 months ago

Mining4 months agoChina Dominates the Supply of U.S. Critical Minerals List

The U.S. Geological Survey estimates that in 2022, China was the world’s leading producer of 30 out of 50 entries on the U.S. critical minerals list.