Mining

The Rush For Jade in British Columbia

The Rush For Jade in British Columbia

Infographic presented by Electra Stone

Many years ago, jade used to travel to China along the Silk Road. Today, more and more jade is being shipped across the Pacific Ocean from British Columbia.

China is the epicenter of jade demand and culture, and today’s infographic shows how jade is formed, the rush for BC jade, and how jade gets from the boulder to the market.

How Jade is Formed

Finding high-quality jade is extremely difficult, which is part of the reason it is so valuable. Jade is created in areas of the world that have subduction zones, such as around the Ring of Fire.

Subduction occurs when two tectonic plates collide and one is forced under the other. The elements are carried deep into the earth, where immense heat and pressure creates the necessary conditions for the formation of jade. This process takes 60 million years.

Most of the world’s jade forms in areas with this kind of intense geological activity. Xinjiang, home to China’s most important nephrite jade deposits, his near where the Indian plate is colliding with the Eurasian plate.

In British Columbia, the conditions are similar, and jade can now be found throughout Canada’s westernmost province. Specifically, there are three areas where today jade is mined: Dease Lake, Mount Ogden, and Cassiar.

The Jade Market

The global market for jade is dominated by Myanmar (formerly Burma) where the majority of jadeite is produced. The size of the reported jade market is largely dependent on data from Myanmar. Before conflict and mine shutdowns resumed in the country in 2011, jade sales were estimated to be $3.5 billion per year.

These shutdowns led to a supply gap in jade, and that is where British Columbia comes in: the production of BC jade has increased from 1.7% to 8.3% from 2011 to 2014.

A 2013 Harvard report put out a more in-depth assessment of the global jade market, and estimated it to be $8 billion.

The BC Jade Market is Booming

Demand for the most desired jade, which comes in an emperor green colour, has put significant price pressure on BC jade. Production of BC jade has doubled, and prices for gem quality jade have jumped to $200-$1,000 per kg.

From Source to Market

BC jade can be found in hard rock deposits or in alluvial boulders that have been moved by glaciers over time.

“New mine jade” refers to jade found in hard rock deposits. This is typically more weathered and more susceptible to cracking.

“Old mine jade” is jade that has been dragged by glaciers in boulder form. Only the best boulders survive, and typically these are of high quality.

Jade is similar to gold in that it can be found in a pure form in nuggets in streams and rivers. Often, the most ambitious Chinese buyers may fly in via helicopter to the northern jade sites to buy jade “off the bucket” in cash. This ensures the best quality jade and miners also benefit.

The jade then typically makes its way to a hub like Vancouver to get shipped overseas to China. China is by far the world’s largest market for jade, where it is considered a hard asset and a symbol of wealth, purity, and spirituality. China is also home to the most brilliant jade craftspeople in the world.

Finally, after sometimes years of intricate carving, the jade is sold in major retail centers like Hong Kong or Beijing. Once a finished product, the jade can sell for up to 10x its original price, creating wealth throughout the value chain.

As an example: the Polar Pride Boulder was carved into a massive Buddha and sold for $1 million in 2004.

Copper

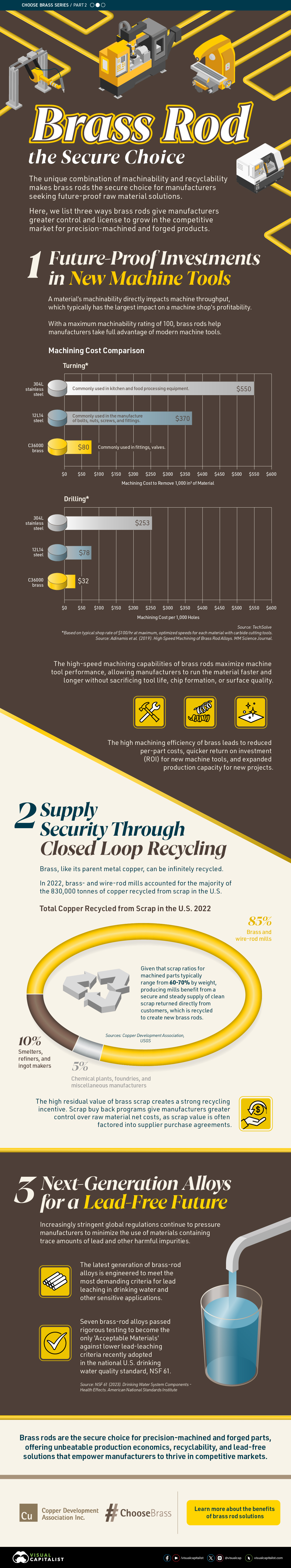

Brass Rods: The Secure Choice

This graphic shows why brass rods are the secure choice for precision-machined and forged parts.

Brass Rods: The Secure Choice

The unique combination of machinability and recyclability makes brass rods the secure choice for manufacturers seeking future-proof raw material solutions.

This infographic, from the Copper Development Association, shows three ways brass rods give manufacturers greater control and a license to grow in the competitive market for precision-machined and forged products.

Future-Proof Investments in New Machine Tools

A material’s machinability directly impacts machine throughput, which typically has the largest impact on machine shop profitability.

The high-speed machining capabilities of brass rods maximize machine tool performance, allowing manufacturers to run the material faster and longer without sacrificing tool life, chip formation, or surface quality.

The high machining efficiency of brass leads to reduced per-part costs, quicker return on investment (ROI) for new machine tools, and expanded production capacity for new projects.

Supply Security Through Closed Loop Recycling

Brass, like its parent element copper, can be infinitely recycled.

In 2022, brass- and wire-rod mills accounted for the majority of the 830,000 tonnes of copper recycled from scrap in the United States.

Given that scrap ratios for machined parts typically range from 60-70% by weight, producing mills benefit from a secure and steady supply of clean scrap returned directly from customers, which is recycled to create new brass rods.

The high residual value of brass scrap creates a strong recycling incentive. Scrap buy back programs give manufacturers greater control over raw material net costs as scrap value is often factored into supplier purchase agreements.

Next Generation Alloys for a Lead-Free Future

Increasingly stringent global regulations continue to pressure manufacturers to minimize the use of materials containing trace amounts of lead and other harmful impurities.

The latest generation of brass-rod alloys is engineered to meet the most demanding criteria for lead leaching in drinking water and other sensitive applications.

Seven brass-rod alloys passed rigorous testing to become the only ‘Acceptable Materials’ against lower lead leaching criteria recently adopted in the national U.S. drinking water quality standard, NSF 61.

Learn more about the advantages of brass rods solutions.

-

Base Metals1 year ago

Base Metals1 year agoRanked: The World’s Largest Copper Producers

Many new technologies critical to the energy transition rely on copper. Here are the world’s largest copper producers.

-

Silver2 years ago

Silver2 years agoMapped: Solar Power by Country in 2021

In 2020, solar power saw its largest-ever annual capacity expansion at 127 gigawatts. Here’s a snapshot of solar power capacity by country.

-

Batteries5 years ago

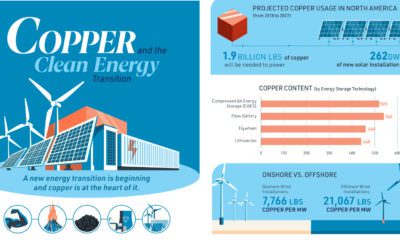

Batteries5 years agoVisualizing Copper’s Role in the Transition to Clean Energy

A clean energy transition is underway as wind, solar, and batteries take center stage. Here’s how copper plays the critical role in these technologies.

-

Science5 years ago

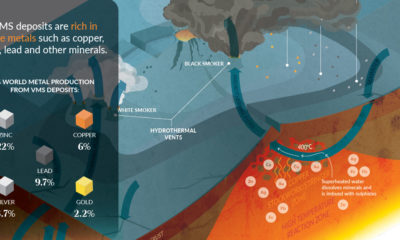

Science5 years agoEverything You Need to Know on VMS Deposits

Deep below the ocean’s waves, VMS deposits spew out massive amounts of minerals like copper, zinc, and gold, making them a key source of the metals…

-

Copper5 years ago

Copper5 years agoHow Much Copper is in an Electric Vehicle?

Have you ever wondered how much copper is in an electric vehicle? This infographic shows the metal’s properties as well as the quantity of copper used.

-

Copper6 years ago

Copper6 years agoCopper: Driving the Green Energy Revolution

Renewable energy is set to fuel a new era of copper demand – here’s how much copper is used in green applications from EVs to photovoltaics.

-

Real Estate2 weeks ago

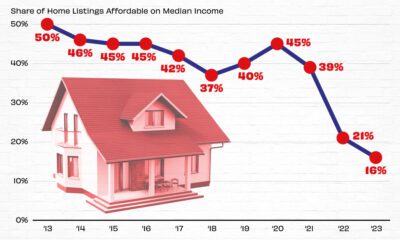

Real Estate2 weeks agoVisualizing America’s Shortage of Affordable Homes

-

Technology1 week ago

Technology1 week agoRanked: Semiconductor Companies by Industry Revenue Share

-

Money1 week ago

Money1 week agoWhich States Have the Highest Minimum Wage in America?

-

Real Estate1 week ago

Real Estate1 week agoRanked: The Most Valuable Housing Markets in America

-

Business2 weeks ago

Business2 weeks agoCharted: Big Four Market Share by S&P 500 Audits

-

AI2 weeks ago

AI2 weeks agoThe Stock Performance of U.S. Chipmakers So Far in 2024

-

Misc2 weeks ago

Misc2 weeks agoAlmost Every EV Stock is Down After Q1 2024

-

Money2 weeks ago

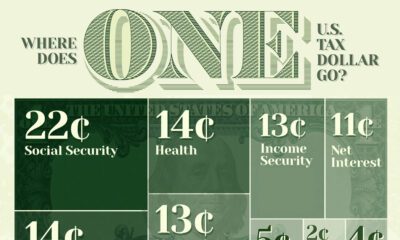

Money2 weeks agoWhere Does One U.S. Tax Dollar Go?