Energy

Tesla’s Origin Story in One Giant Infographic

Priced at $17 per share just seven years ago, the Tesla IPO ended up being a total bargain for anyone lucky enough to get in.

However, this view comes with the benefit of plenty of hindsight – and even Elon Musk would tell you that it wasn’t always obvious that the company would be around in 2017. There were periods of time when layoffs were rampant, the company’s payroll was covered by credit cards, and Tesla was on the brink of bankruptcy.

Rise of Tesla: The History (Part 1 of 3)

Today’s massive infographic comes to us from Global Energy Metals, and it is the first part of our three-part Rise of Tesla Series, which will soon be a definitive source for everything you ever wanted to know about the company.

Part 1 deals with the origin story of the company, challenges faced by the first EVs, the company’s strategy and initial execution, and the Tesla Roadster’s development.

Tesla was initially conceived in 2003 out of the vision of two Silicon Valley engineers, Martin Eberhard and Marc Tarpenning. The partners had just sold their eReader company for $187 million, and were looking for their next big idea.

The infamous “death” of GM’s EV1 electric car that year ended up being a source of inspiration, and the two engineers started looking into ways to reduce the world’s reliance on Middle Eastern oil and to combat climate change.

The electric car pathway was not just better than the other choices that were out there – it was dramatically better.

– Martin Eberhard, Tesla co-founder

The company was bootstrapped until Elon Musk led the $7.5 million Series A round in February 2004 and became the controlling investor. He joined the board of directors as its chairman, and took on operational roles as well.

At this time, JB Straubel – who famously rebuilt an electric golf cart when he was only 14 years old – also joined the company as CTO.

Initial Strategy

Tesla’s initial strategy was to build a high performance sports car first, for a few reasons:

- It would shed the existing stigma around EVs

- Sports cars have higher margins

- Fewer cars would need to be produced

- High-end buyers are less price-sensitive

Instead of building the Tesla Roadster from scratch, the company aimed to combine an existing chassis with an AC induction motor and battery. And so, the company signed a contract with British sports car maker Lotus to use its Elise chassis as a base.

Roadster Debut

The Roadster made its debut at a star-studded launch party in Santa Monica. The 350-strong guestlist of Hollywood celebrities and the press were wowed by the 2-seater sports car with a $100,000 price tag.

This is not your father’s electric car.

– The Washington Post

What the audience didn’t notice?

The Roadsters had many issues that needed to be fixed – these and others would delay Tesla well beyond the planned Summer 2007 delivery date.

The Dark Years

Tesla’s original business plan was built on the idea that the auto industry had changed drastically.

Automakers now focused on core competencies like financing, engine design, sales and marketing, and final assembly – getting the hundreds of individual car parts, like windshield wiper blades or door handles, was actually outsourced.

This was supposed to make it easy for Tesla to get its foot in the door – to focus on the EV aspect and let Lotus do the rest. Instead, the company experienced an “elegance creep” phenomenon. They were able to keep making the car nicer, but it meant customizing individual parts.

Costs spiraled out of control, things got delayed, and the car began to take a very different shape than the Elise. By the time it was said and done, the Tesla Roadster was nothing like its Lotus cousin, sharing only 7% parts by count.

The Revolving Door

During this process, there was a revolving door of CEOs.

2007: Eberhart was forced to resign as CEO in August

2007: Early Tesla investor Michael Marks took the reins temporarily

2007: In November, Ze’ev Drori took over as CEO and President

2008: After less than a year of Drori’s run, Musk stepped in to take over the role in October

At this point, Musk had already invested $55 million in the company, and it was teetering towards bankruptcy.

I’ve got so many chips on the table with Tesla. It just made sense for me to have both hands on the wheel.

– Elon Musk

Some of Musk’s first moves:

- He ended up cutting 25% of the workforce

- He leaned on friends to help cover payroll, week-to-week

- He raised a $40 debt financing round to escape bankruptcy

- He formed a strategic partnership with Daimler AG, which acquired a 10% stake of Tesla for $50 million

- He took a $465 million loan from the U.S. Dept. of Energy (He repaid it back ahead of the deadline)

- He recalled 75% of the Roadsters produced between March 2008 and April 2009

Despite revamping the entire production process – and the company itself – Tesla made it through its most trying time.

The Roadster’s Run

The Roadster wasn’t perfect, but it helped Tesla learn what it meant to be a car company.

It is not just a car, but one of the strongest automotive statements on the road.

– Car and Driver

A total of 2,450 units were produced, and the specs were impressive for an EV. With a top speed of 125 mph and a 0-60 mph time of 3.7 seconds, the Roadster helped dispel many of the myths surrounding electric cars.

Meanwhile, the Roadster’s lithium-ion battery also was the first step forward in an entire battery revolution. The 992 lb (450 kg) battery for the Roadster contained 6,831 lithium ion cells arranged into 11 “sheets” connected in series, and gave the car a range of 244 miles.

With the Roadster, Tesla would not only set itself up for future success, but also the transformation of an entire industry.

This was Part 1 of the Tesla Series. Parts 2 and 3, on Tesla as well as the future vision, will be released in the near future!

Lithium

Ranked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

The Top 10 EV Battery Manufacturers in 2023

This was originally posted on our Voronoi app. Download the app for free on iOS or Android and discover incredible data-driven charts from a variety of trusted sources.

Despite efforts from the U.S. and EU to secure local domestic supply, all major EV battery manufacturers remain based in Asia.

In this graphic we rank the top 10 EV battery manufacturers by total battery deployment (measured in megawatt-hours) in 2023. The data is from EV Volumes.

Chinese Dominance

Contemporary Amperex Technology Co. Limited (CATL) has swiftly risen in less than a decade to claim the title of the largest global battery group.

The Chinese company now has a 34% share of the market and supplies batteries to a range of made-in-China vehicles, including the Tesla Model Y, SAIC’s MG4/Mulan, and various Li Auto models.

| Company | Country | 2023 Production (megawatt-hour) | Share of Total Production |

|---|---|---|---|

| CATL | 🇨🇳 China | 242,700 | 34% |

| BYD | 🇨🇳 China | 115,917 | 16% |

| LG Energy Solution | 🇰🇷 Korea | 108,487 | 15% |

| Panasonic | 🇯🇵 Japan | 56,560 | 8% |

| SK On | 🇰🇷 Korea | 40,711 | 6% |

| Samsung SDI | 🇰🇷 Korea | 35,703 | 5% |

| CALB | 🇨🇳 China | 23,493 | 3% |

| Farasis Energy | 🇨🇳 China | 16,527 | 2% |

| Envision AESC | 🇨🇳 China | 8,342 | 1% |

| Sunwoda | 🇨🇳 China | 6,979 | 1% |

| Other | - | 56,040 | 8% |

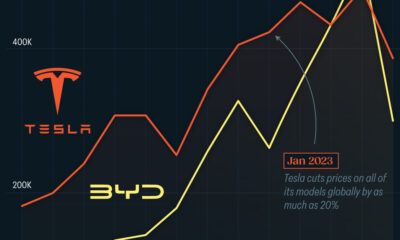

In 2023, BYD surpassed LG Energy Solution to claim second place. This was driven by demand from its own models and growth in third-party deals, including providing batteries for the made-in-Germany Tesla Model Y, Toyota bZ3, Changan UNI-V, Venucia V-Online, as well as several Haval and FAW models.

The top three battery makers (CATL, BYD, LG) collectively account for two-thirds (66%) of total battery deployment.

Once a leader in the EV battery business, Panasonic now holds the fourth position with an 8% market share, down from 9% last year. With its main client, Tesla, now sourcing batteries from multiple suppliers, the Japanese battery maker seems to be losing its competitive edge in the industry.

Overall, the global EV battery market size is projected to grow from $49 billion in 2022 to $98 billion by 2029, according to Fortune Business Insights.

-

Money2 weeks ago

Money2 weeks agoWhich States Have the Highest Minimum Wage in America?

-

Misc1 week ago

Misc1 week agoAirline Incidents: How Do Boeing and Airbus Compare?

-

Environment1 week ago

Environment1 week agoTop Countries By Forest Growth Since 2001

-

United States2 weeks ago

United States2 weeks agoWhere U.S. Inflation Hit the Hardest in March 2024

-

Demographics2 weeks ago

Demographics2 weeks agoThe Smallest Gender Wage Gaps in OECD Countries

-

Markets2 weeks ago

Markets2 weeks agoThe Top 10 States by Real GDP Growth in 2023

-

Countries2 weeks ago

Countries2 weeks agoPopulation Projections: The World’s 6 Largest Countries in 2075

-

Travel2 weeks ago

Travel2 weeks agoRanked: The World’s Top Flight Routes, by Revenue