Mining

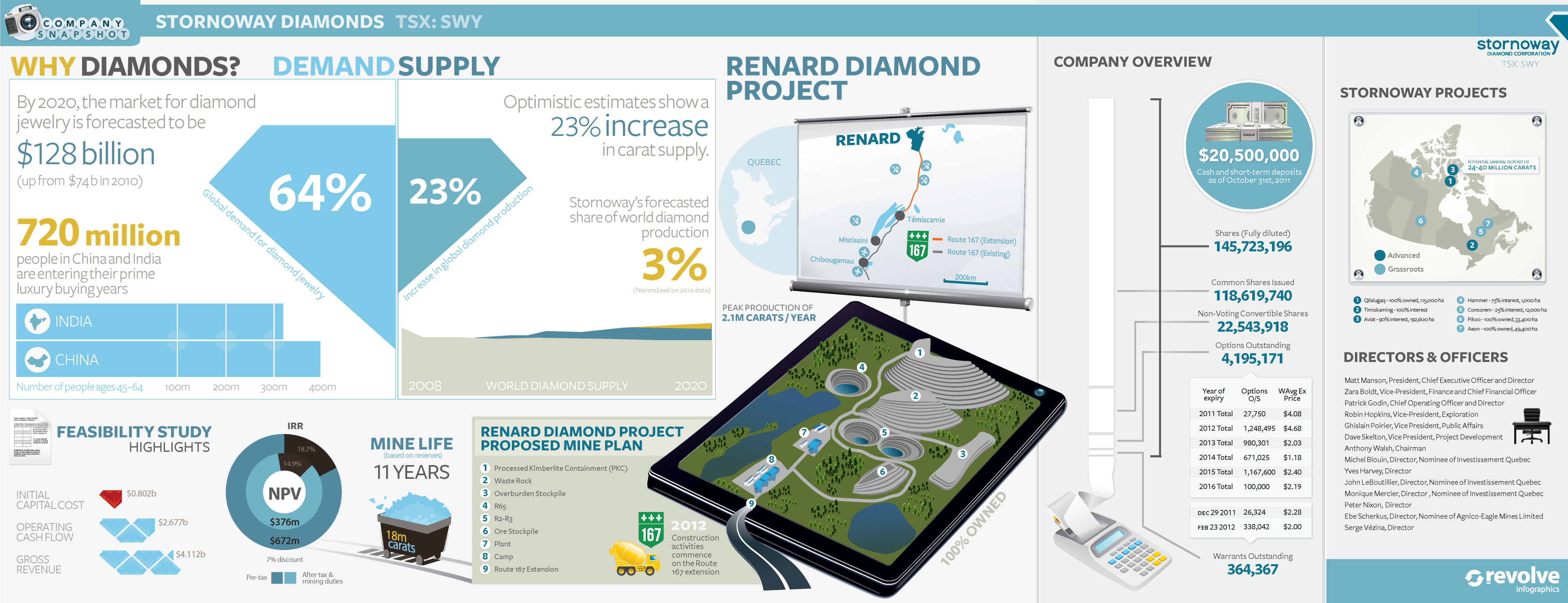

Stornoway Diamonds (TSX:SWY)

Stornoway is building Quebec’s first diamond mine at it s 100% Renard Project

Forward looking information

This infographic contains “forward-looking information” within the meaning of Canadian securities legislation and “forward-looking statements” within the meaning of the United States Private Securities Litigation Reform Act of 1995. This information and these statements, referred to herein as “forward-looking statements”, are made as of the date of this presentation and the Company does not intend, and does not assume any

obligation, to update these forward-looking statements, except as required by law.

Forward-looking statements relate to future events or future performance and reflect current expectations or beliefs regarding future events and

include, but are not limited to, statements with respect to: (i) the amount of mineral resources and exploration targets; (ii) the amount of future

production over any period; (iii) net present value and internal rates of return of the mining operation; (iv) capital costs and operating costs; (v) mine expansion potential and expected mine life; (vi) expected time frames for completion of permitting and regulatory approvals and making a production decision; (vii) future exploration plans; (viii) future market prices for rough diamonds; and (ix) sources of and anticipated financing requirements. Any statements that express or involve discussions with respect to predictions, expectations, beliefs, plans, projections, objectives,

assumptions or future events or performance (often, but not always, using words or phrases such as “expects”, “anticipates”, “plans”, “projects”,

“estimates”, “assumes”, “intends”, “strategy”, “goals”, “objectives” or variations thereof or stating that certain actions, events or results “may”,

“could”, “would”, “might” or “will” be taken, occur or be achieved, or the negative of any of these terms and similar expressions) are not statements

of historical fact and may be forward-looking statements.

Forward-looking statements are made based upon certain assumptions and other important factors that, if untrue, could cause the actual results,

performances or achievements of Stornoway to be materially different from future results, performances or achievements expressed or implied by

such statements. Such statements and information are based on numerous assumptions regarding present and future business strategies and the

environment in which Stornoway will operate in the future, including the price of diamonds, anticipated costs and ability to achieve goals. Certain

important factors that could cause actual results, performances or achievements to differ materially from those in the forward-looking statements

include, but are not limited to: (i) estimated completion date for the Environmental and Social Impact Assessment; (ii) required capital investment

and estimated workforce requirements; (iii) estimates of net present value and internal rates of return; (iv) receipt of regulatory approvals on

acceptable terms within commonly experienced time frames; (v) the assumption that a production decision will be made, and that decision will be

positive; (vi) anticipated timelines for the commencement of mine production; (vii) anticipated timelines related to the Route 167 extension and the

impact on the development schedule at Renard; (viii) anticipated timelines for community consultations and the conclusion of an Impact and

Benefits Agreement; (ix) market prices for rough diamonds and the potential impact on the Renard Project’s value; and (x) future exploration plans

and objectives. Additional risks are described in Stornoway’s most recently filed Annual Information Form, annual and interim MD&A, and other

disclosure documents available under the Company’s profile at: www.sedar.com.

When relying on our forward-looking statements to make decisions with respect to Stornoway, investors and others should carefully consider the

foregoing factors and other uncertainties and potential events. Stornoway does not undertake to update any forward-looking statement, whether

written or oral, that may be made from time to time by Stornoway or on our behalf, except as required by law.

Copper

Brass Rods: The Secure Choice

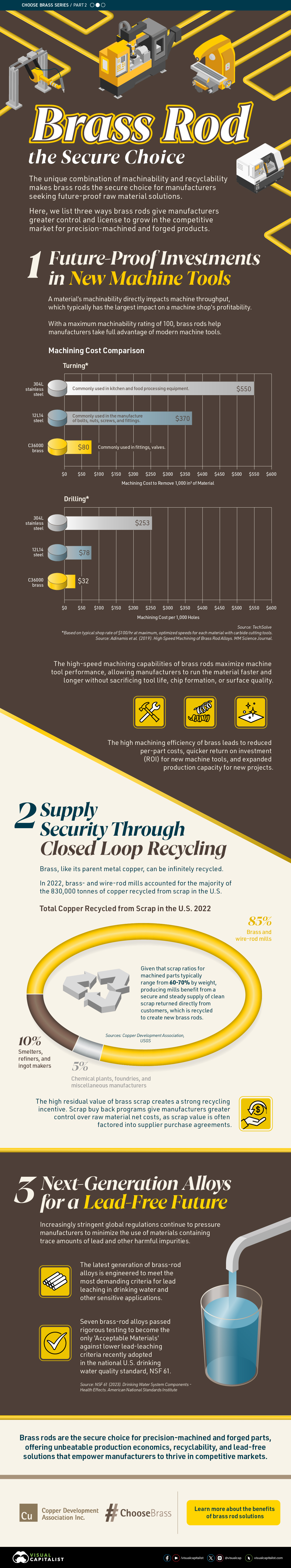

This graphic shows why brass rods are the secure choice for precision-machined and forged parts.

Brass Rods: The Secure Choice

The unique combination of machinability and recyclability makes brass rods the secure choice for manufacturers seeking future-proof raw material solutions.

This infographic, from the Copper Development Association, shows three ways brass rods give manufacturers greater control and a license to grow in the competitive market for precision-machined and forged products.

Future-Proof Investments in New Machine Tools

A material’s machinability directly impacts machine throughput, which typically has the largest impact on machine shop profitability.

The high-speed machining capabilities of brass rods maximize machine tool performance, allowing manufacturers to run the material faster and longer without sacrificing tool life, chip formation, or surface quality.

The high machining efficiency of brass leads to reduced per-part costs, quicker return on investment (ROI) for new machine tools, and expanded production capacity for new projects.

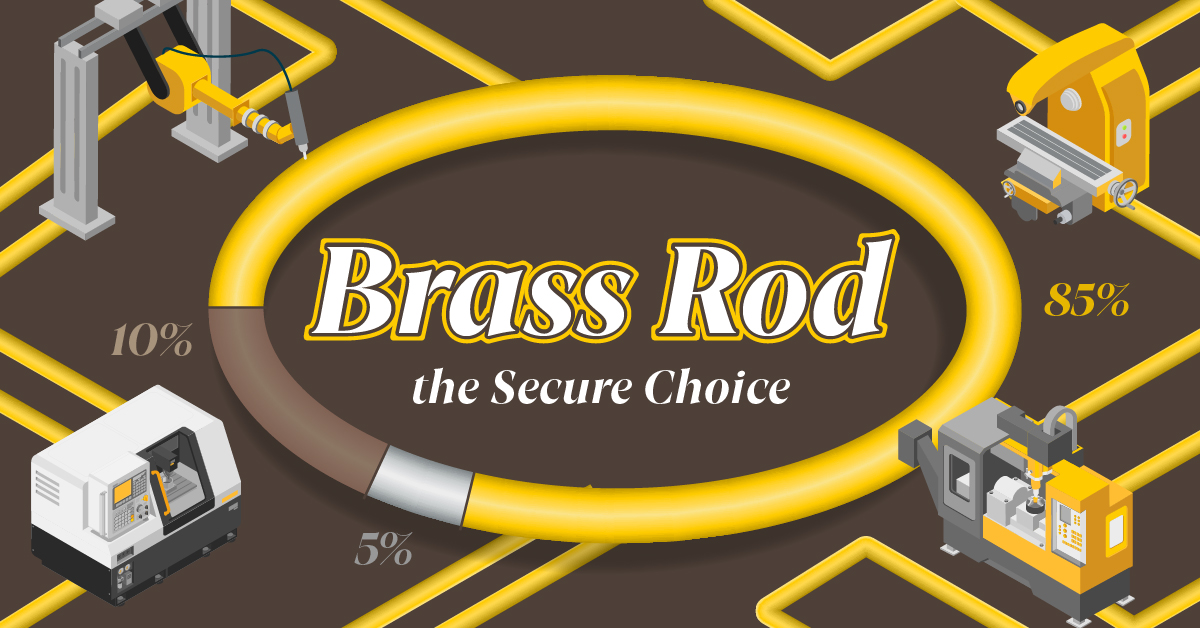

Supply Security Through Closed Loop Recycling

Brass, like its parent element copper, can be infinitely recycled.

In 2022, brass- and wire-rod mills accounted for the majority of the 830,000 tonnes of copper recycled from scrap in the United States.

Given that scrap ratios for machined parts typically range from 60-70% by weight, producing mills benefit from a secure and steady supply of clean scrap returned directly from customers, which is recycled to create new brass rods.

The high residual value of brass scrap creates a strong recycling incentive. Scrap buy back programs give manufacturers greater control over raw material net costs as scrap value is often factored into supplier purchase agreements.

Next Generation Alloys for a Lead-Free Future

Increasingly stringent global regulations continue to pressure manufacturers to minimize the use of materials containing trace amounts of lead and other harmful impurities.

The latest generation of brass-rod alloys is engineered to meet the most demanding criteria for lead leaching in drinking water and other sensitive applications.

Seven brass-rod alloys passed rigorous testing to become the only ‘Acceptable Materials’ against lower lead leaching criteria recently adopted in the national U.S. drinking water quality standard, NSF 61.

Learn more about the advantages of brass rods solutions.

-

Base Metals1 year ago

Base Metals1 year agoRanked: The World’s Largest Copper Producers

Many new technologies critical to the energy transition rely on copper. Here are the world’s largest copper producers.

-

Silver2 years ago

Silver2 years agoMapped: Solar Power by Country in 2021

In 2020, solar power saw its largest-ever annual capacity expansion at 127 gigawatts. Here’s a snapshot of solar power capacity by country.

-

Batteries5 years ago

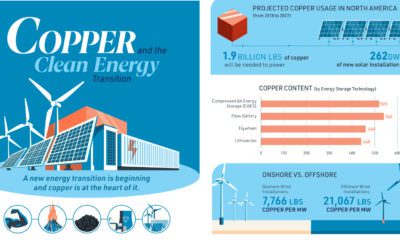

Batteries5 years agoVisualizing Copper’s Role in the Transition to Clean Energy

A clean energy transition is underway as wind, solar, and batteries take center stage. Here’s how copper plays the critical role in these technologies.

-

Science5 years ago

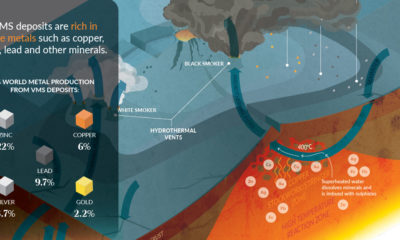

Science5 years agoEverything You Need to Know on VMS Deposits

Deep below the ocean’s waves, VMS deposits spew out massive amounts of minerals like copper, zinc, and gold, making them a key source of the metals…

-

Copper5 years ago

Copper5 years agoHow Much Copper is in an Electric Vehicle?

Have you ever wondered how much copper is in an electric vehicle? This infographic shows the metal’s properties as well as the quantity of copper used.

-

Copper6 years ago

Copper6 years agoCopper: Driving the Green Energy Revolution

Renewable energy is set to fuel a new era of copper demand – here’s how much copper is used in green applications from EVs to photovoltaics.

-

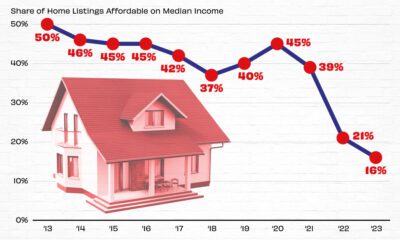

Real Estate2 weeks ago

Real Estate2 weeks agoVisualizing America’s Shortage of Affordable Homes

-

Technology1 week ago

Technology1 week agoRanked: Semiconductor Companies by Industry Revenue Share

-

Money2 weeks ago

Money2 weeks agoWhich States Have the Highest Minimum Wage in America?

-

Real Estate2 weeks ago

Real Estate2 weeks agoRanked: The Most Valuable Housing Markets in America

-

Business2 weeks ago

Business2 weeks agoCharted: Big Four Market Share by S&P 500 Audits

-

AI2 weeks ago

AI2 weeks agoThe Stock Performance of U.S. Chipmakers So Far in 2024

-

Misc2 weeks ago

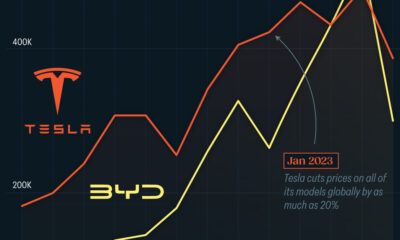

Misc2 weeks agoAlmost Every EV Stock is Down After Q1 2024

-

Money2 weeks ago

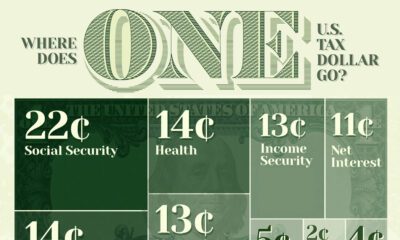

Money2 weeks agoWhere Does One U.S. Tax Dollar Go?