Mining

Extraordinary Raw Materials in a Tesla Model S

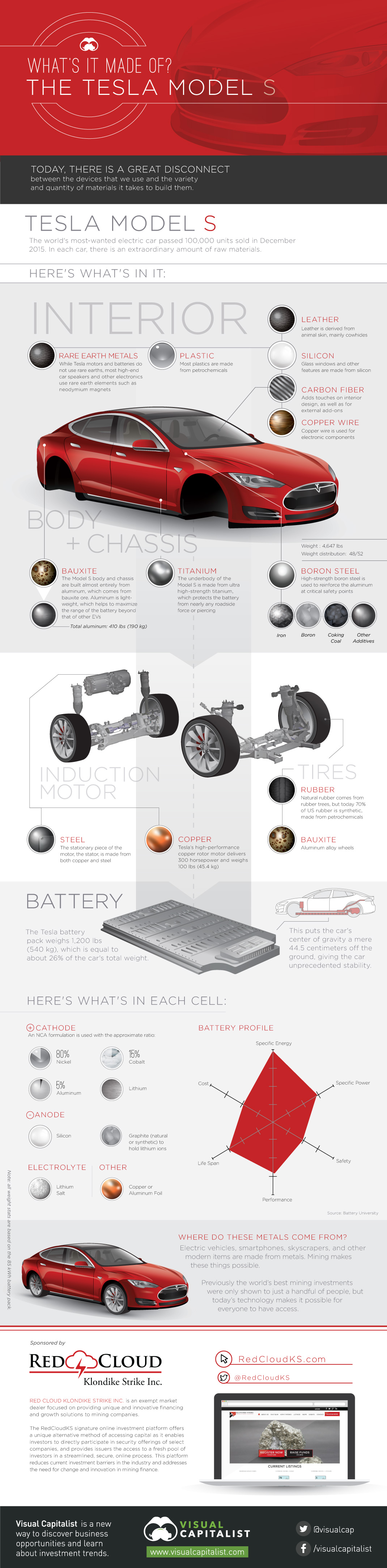

The Extraordinary Raw Materials in a Tesla Model S

Presented by: Red Cloud Klondike Strike (Equity crowdfunding in mining)

The Tesla Model S is the world’s most-wanted electric car, with 100,000 units already sold as of December 2015.

Critics have lauded the car for its impressive safety rating, range, and design. However, it is also worth considering that it is the incredible raw materials that go into the Tesla Model S that help to make all of these things possible.

Here’s what’s in a Tesla Model S:

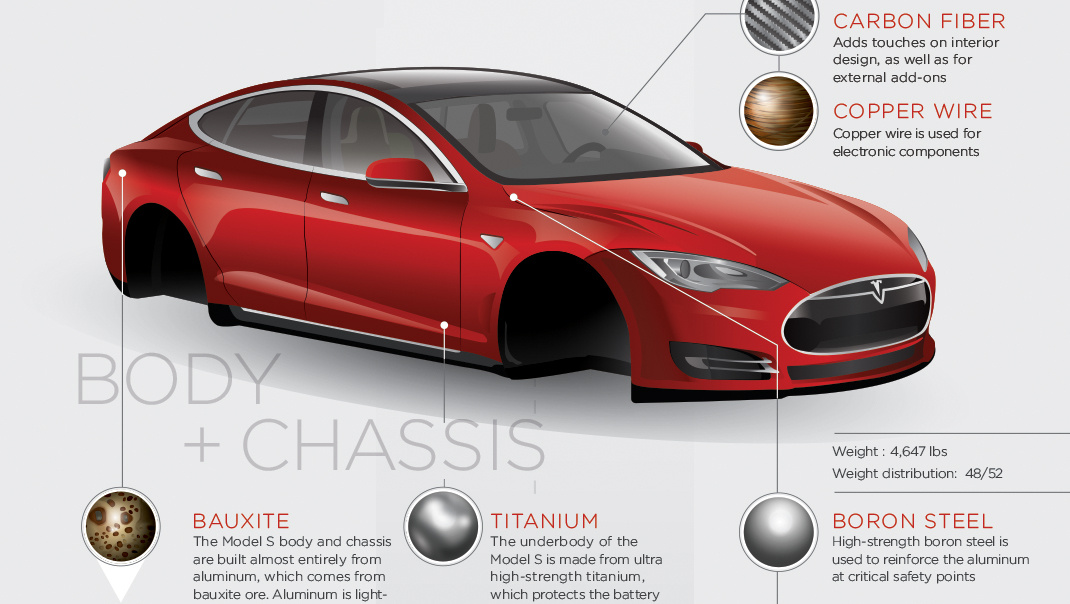

Body and Chassis

Bauxite: The Tesla Model S body and chassis are built almost entirely from aluminum, which comes from bauxite ore. Aluminum is lightweight, which helps to maximize the range of the battery beyond that of other EVs. The total amount of aluminum used in the car is 410 lbs (190 kg).

Boron steel: High-strength boron steel is used to reinforce the aluminum at critical safety points. Boron steel is made from iron, boron, coking coal, and other additives.

Titanium: The underbody of the Tesla Model S is made from ultra high-strength titanium, which protects the battery from nearly any roadside force or piercing.

Interior

Rare Earth Metals: While Tesla engines and batteries do not use rare earths, most high-end car speakers and other electronics use rare earth elements such as neodymium magnets.

Plastic: Most plastics are made from petrochemicals.

Leather: Leather is derived from animal skin, mainly cowhides .

Silicon: Glass windows and other features are made from silicon.

Carbon fiber and copper wire are also used within the interior for various components.

Wheels

Bauxite: Aluminum alloy wheels are also made from bauxite ore.

Rubber: Natural rubber comes from rubber trees, but today 70% of US rubber is synthetic, made from petrochemicals.

Induction Engine:

Copper: Tesla’s high-performance copper rotor motor delivers 300 horsepower and weighs 100 lbs (45.4 kg).

Steel: The stationary piece of the engine, the stator, is made from both copper and steel.

Battery:

The Tesla battery pack weighs 1,200 lbs (540 kg), which is equal to about 26% of the car’s total weight. This puts the car’s center of gravity a mere 44.5 centimeters off the ground, giving the car unprecedented stability.

The battery itself contains 7,104 lithium-ion battery cells. Here’s what’s in each cell:

Cathode: The Tesla Model S battery cathode uses an NCA formulation with the approximate ratio: 80% nickel, 15% cobalt, and 5% aluminum. Small amounts of lithium are also used in the cathode.

Anode: The negative terminal uses natural or synthetic graphite to hold lithium ions. Small amounts of silicon are also likely used in the anode as well.

Electrolyte: The electrolyte is made of a lithium salt.

Copper and/or aluminum foil is also used in the battery as well.

Note: all numbers above are based on the 85 kWh battery model.

Lithium

Ranked: The Top 10 EV Battery Manufacturers in 2023

Asia dominates this ranking of the world’s largest EV battery manufacturers in 2023.

The Top 10 EV Battery Manufacturers in 2023

This was originally posted on our Voronoi app. Download the app for free on iOS or Android and discover incredible data-driven charts from a variety of trusted sources.

Despite efforts from the U.S. and EU to secure local domestic supply, all major EV battery manufacturers remain based in Asia.

In this graphic we rank the top 10 EV battery manufacturers by total battery deployment (measured in megawatt-hours) in 2023. The data is from EV Volumes.

Chinese Dominance

Contemporary Amperex Technology Co. Limited (CATL) has swiftly risen in less than a decade to claim the title of the largest global battery group.

The Chinese company now has a 34% share of the market and supplies batteries to a range of made-in-China vehicles, including the Tesla Model Y, SAIC’s MG4/Mulan, and various Li Auto models.

| Company | Country | 2023 Production (megawatt-hour) | Share of Total Production |

|---|---|---|---|

| CATL | 🇨🇳 China | 242,700 | 34% |

| BYD | 🇨🇳 China | 115,917 | 16% |

| LG Energy Solution | 🇰🇷 Korea | 108,487 | 15% |

| Panasonic | 🇯🇵 Japan | 56,560 | 8% |

| SK On | 🇰🇷 Korea | 40,711 | 6% |

| Samsung SDI | 🇰🇷 Korea | 35,703 | 5% |

| CALB | 🇨🇳 China | 23,493 | 3% |

| Farasis Energy | 🇨🇳 China | 16,527 | 2% |

| Envision AESC | 🇨🇳 China | 8,342 | 1% |

| Sunwoda | 🇨🇳 China | 6,979 | 1% |

| Other | - | 56,040 | 8% |

In 2023, BYD surpassed LG Energy Solution to claim second place. This was driven by demand from its own models and growth in third-party deals, including providing batteries for the made-in-Germany Tesla Model Y, Toyota bZ3, Changan UNI-V, Venucia V-Online, as well as several Haval and FAW models.

The top three battery makers (CATL, BYD, LG) collectively account for two-thirds (66%) of total battery deployment.

Once a leader in the EV battery business, Panasonic now holds the fourth position with an 8% market share, down from 9% last year. With its main client, Tesla, now sourcing batteries from multiple suppliers, the Japanese battery maker seems to be losing its competitive edge in the industry.

Overall, the global EV battery market size is projected to grow from $49 billion in 2022 to $98 billion by 2029, according to Fortune Business Insights.

-

Green1 week ago

Green1 week agoRanked: The Countries With the Most Air Pollution in 2023

-

Misc2 weeks ago

Misc2 weeks agoAlmost Every EV Stock is Down After Q1 2024

-

AI2 weeks ago

AI2 weeks agoThe Stock Performance of U.S. Chipmakers So Far in 2024

-

Markets2 weeks ago

Markets2 weeks agoCharted: Big Four Market Share by S&P 500 Audits

-

Real Estate2 weeks ago

Real Estate2 weeks agoRanked: The Most Valuable Housing Markets in America

-

Money2 weeks ago

Money2 weeks agoWhich States Have the Highest Minimum Wage in America?

-

AI2 weeks ago

AI2 weeks agoRanked: Semiconductor Companies by Industry Revenue Share

-

Travel2 weeks ago

Travel2 weeks agoRanked: The World’s Top Flight Routes, by Revenue